Guide to Dye Penetrant Testing

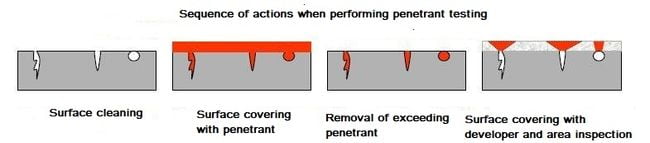

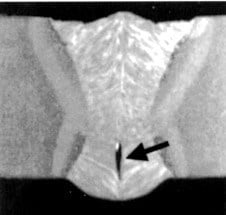

In the world of non-destructive testing (NDT), dye penetrant testing is a widely employed method for detecting surface-breaking defects in various materials, including metals, plastics, and ceramics. This technique, often referred to as liquid penetrant inspection or simply penetrant testing, plays a crucial role in ensuring the structural integrity and safety of a wide range […]