Carbon Equivalent in welding metallurgy Calculator below for use

In welding and steel fabrication, Carbon Equivalent (CE) is one of the most important parameters engineers and quality professionals must understand. CE predicts how steel will behave during welding by assessing its weldability and hardenability. Instead of looking at carbon content alone, CE combines carbon with other alloying elements like manganese (Mn), chromium (Cr), molybdenum (Mo), vanadium (V), nickel (Ni), and copper (Cu) into a single calculated value.

The higher the CE, the greater the risk of cracking in the heat-affected zone (HAZ), requiring more stringent welding controls such as preheating, controlled cooling, or post-weld heat treatment (PWHT).

Why Carbon Equivalent Matters in Welding

CE plays a central role in determining whether steel can be welded successfully without defects. Some key reasons why CE is important:

- Predicts Weldability: CE indicates how easily a steel can be welded without cracking or other metallurgical problems.

- Guides Preheat & PWHT Needs: Higher CE values often require preheating and sometimes PWHT to avoid cracking.

- Assesses HAZ Hardness & Cracking Risk: CE helps estimate hardness in the heat-affected zone and highlights susceptibility to hydrogen-induced cracking (HIC).

- Improves Reliability: By applying CE calculations, engineers can ensure better weld quality, reduce failures, and optimize project timelines.

Common Formulas for Carbon Equivalent

There are several formulas to calculate CE, but the two most widely used are:

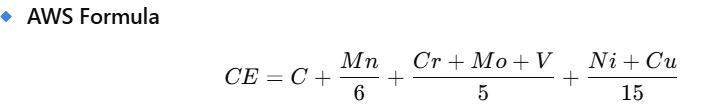

🔹 AWS Formula

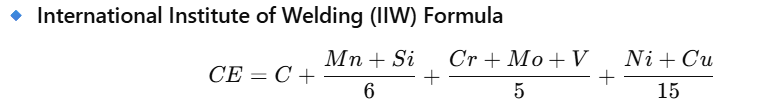

🔹 International Institute of Welding (IIW) Formula

While both formulas provide a reliable prediction of weldability, the choice often depends on industry standards and client specifications.

Effect of Alloying Elements on CE

Each element in steel affects weldability differently:

- Carbon (C): Raises hardness and cracking risk, lowers weldability.

- Manganese (Mn): Improves strength and hardenability but increases susceptibility to cracking.

- Chromium (Cr), Molybdenum (Mo), Vanadium (V): Increase HAZ hardness and hardenability.

- Nickel (Ni), Copper (Cu): Enhance toughness and corrosion resistance but slightly increase hardness.

This balance of elements makes CE a more accurate predictor than carbon content alone.

Weldability Thresholds Based on CE

| CE Value | Weldability | Recommendations |

|---|---|---|

| < 0.40% | Excellent | No preheat needed, low crack risk. |

| 0.40 – 0.45% | Good (with caution) | Monitor heat input, preheat thicker sections. |

| 0.45 – 0.50% | Caution Zone | Preheat necessary to prevent cracking. |

| 0.50 – 0.60% | High Risk | Preheat & possible PWHT required. |

| > 0.60% | Very High Risk | Strict welding controls & thorough inspection required. |

Weldability Improvement Strategies for High CE Steels

When steels have high CE values, special precautions are required to ensure defect-free welding:

- Preheating: Reduces hardening, ensures uniform cooling, and lowers cracking risk.

- Controlled Cooling: Helps mitigate hydrogen cracking and controls cooling rates.

- Low-Hydrogen Electrodes: Prevent hydrogen-induced cracking, improving weld soundness.

- Post-Weld Heat Treatment (PWHT): Relieves residual stresses, reduces cracking, and improves toughness.

Field Application Tips

Practical considerations for engineers and welding inspectors include:

- Always verify CE from Material Test Certificates (MTC) before welding.

- Adjust Welding Procedure Specifications (WPS) according to CE values.

- Implement preheating and PWHT when required.

- Closely monitor cooling rates to avoid hydrogen-induced cracking.

Challenges with High CE Steels

While steels with higher CE values provide strength and hardness, they come with challenges:

- Higher risk of cold cracking in HAZ.

- Strict temperature control required during welding.

- Extra costs & time for preheating and PWHT.

- Possible project delays if CE is not properly accounted for.

Key Takeaways

- Carbon Equivalent (CE) is a calculated value that combines carbon and alloying elements to predict steel’s weldability.

- Lower CE (<0.40%) steels are easier to weld, while higher CE steels require more control and precaution.

- CE is crucial for cracking risk assessment, preheat planning, and welding procedure design.

- Effective CE management ensures safer, high-quality welds with fewer reworks and failures.

- Understanding and applying CE values improves structural integrity and project success in steel fabrication and construction.

✅ In summary: Mastering the concept of Carbon Equivalent is not just about calculating a number—it’s about making informed welding decisions that improve safety, reduce costs, and guarantee quality.