This article is regarding the benefits of weld consumable calculation. Steps to calculate weld consumable & we will calculate weld consumable for single “V” groove joint. You can also download our simplified weld consumable calculator for single V groove joints, Single V branch Joints, Fillet joints, deposition efficiency, electrode calculator for SMAW welding process, Importance of stub length etc. from below link

In welding, weld consumable estimation plays the vital role for complete the fabrication within time frame and at the possible minimum cost of weld metal as other cost of welding are fixed. There are many benefits of weld deposition calculation which are briefed below

Weld Consumable Excel Calculator Download Link

Weld Consumable Calculation PPT Free Download For Training

Welding Symbols PPT Free Download For Training

- Welding cost can be minimized as required amount of consumable will be purchased.

- Last time hiccups can be avoid as we know the required quantity of consumable.

- Inventory problem can be resolved as required amount of consumable will be purchased.

- When we need to supply consumable to vendor we can supply the required quantity only.

- Early negotiations can be done with the supplier as per the quantity of the consumable.

- Wastage of consumable can be monitored easily if we know the consumable quantity to be consumed.

Above points illustrates the importance of weld consumable calculation. But many of our friends don’t know the basics of the weld consumable calculation in this article we will try to clear the basics of weld consumable calculation with a simple V groove design.

Steps to do Weld Consumable Calculation for Weld Joints

- Details of groove design.

- Calculate the area of the groove design. (including reinforcement)

- Calculate volume by multiplying the groove area with length of the weld. ( Volume = Area X Length)

- Multiply the weld volume with the density of the material to be deposited. (Weight = Volume X Density)

- Since we get the required weld deposit for to fill-up groove, for welding electrode required in Kgs multiply with the deposition factors mentioned in table 1 for different welding processes.

Deposition Efficiency of Different Welding Process

| Table 1 | ||

| Sr. No. | Welding Process | Deposition Efficiency |

| 1 | Gas Tungstun Arc Welding (GTAW/TIG) | 95-98% |

| 2 | Sheilded Metal Arc Welding (SMAW) | 60-65% |

| 3 | Gas Metal Arc Welding (GMAW) | 95-99% |

| 4 | Flux Cored Arc Welding (FCAW) | 80-85% |

| 5 | Submerged Arc Welding (SAW) | 99% excluding flux |

Steps to calculate weld consumable prior to fabrication:

Let’s now calculate weld consumable required for the welding of ‘Single V Groove joint’, dimensions of groove are as mentioned below

Thickness of groove (T) : 15 mm

Bevel angle : 35°

Root Gap (G): 3 mm

Reinforcement (R ): 3 mm

Length of weld (L): 1000 mm

Material CS Density (ρ) : 7.85 (gm/cm3)

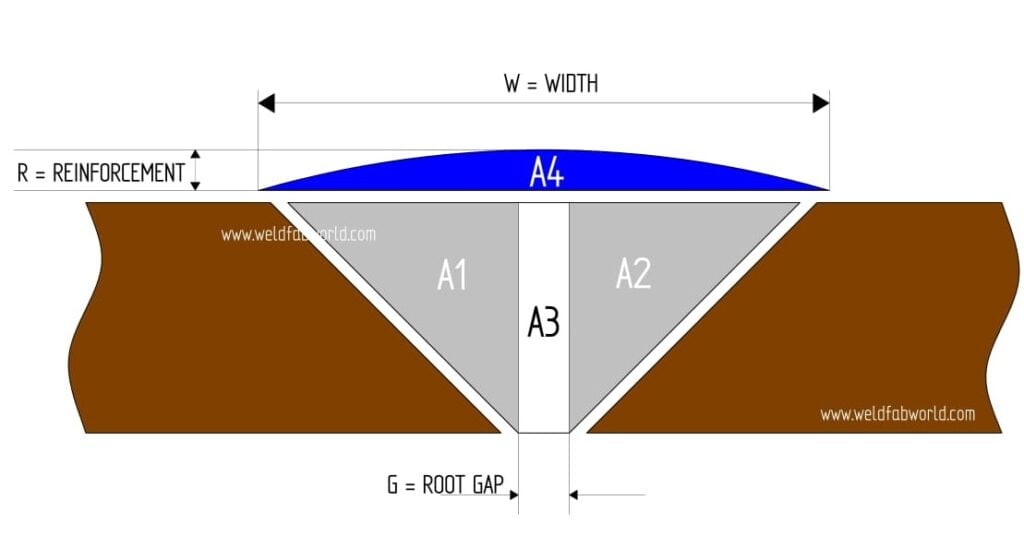

For calculation of area breakdown the groove design in the simplest form to calculate area, as shown in below figure we have cut the groove design in 4 parts so area can be calculated easily

Area of Part 3 (A3) : This part is a rectangle and area for rectangle is Length X Breadth

Length = 15 mm (Thickness of Groove) & Breadth = 3 mm (Root Gap of Groove)

Area of part 3 (A3)= 15 mm x 3 mm = 45 mm2

Area of Part 1 & 2 (A1 & A2) : As these parts are triangle and the area for triangle is ½ X base X Height. Also part 2 and 3 has same bevel angle and thickness so area of both the parts will be equal.

So we will calculate area of any of one and other part will have same area.

We will calculate area for part 1

Height (Thickness of base material) = 15 mm

Base = tan35° X Height (Thickness of base metal) = tan35° X 15 mm = 10.503 mm

Area of part 1 = ½ X 10.503 X 15 = 78.7725 mm2

Area of part 2 (Same as area of part 1) = ½ X 7.095 X 15 = 78.7725 mm2

Area for part 4 (A4): The area of part will be approximately equal to Height of Cap(Reinforcement) Multiplied by Width of Cap(Reinforcement)

Height reinforcement = 3 mm

Width of reinforcement = 2 (tan35° X Thickness of base metal) + Root Gap

Width of reinforcement = (2(tan35° X 15)+3)+ = 24.006 mm

Area of Part 4 = (24.006 X 3) = 72.0186 mm2

Total Area of Groove = Area of Part 1 + Area of Part 2 + Area of Part 3 + Area of Part 4

Total Area of Groove = 45 + 78.7725 + 78.7725 + 72.0186 =274.5636 mm2

Total Volume of Joint = Area of groove X Weld Length

= 274.5636 x 1000 (Considering weld length 1000mm)= 274563 mm3

Weight of required weld consumable =Volume X Density

To get weight in KG = Volume (mm3) X Density (g/cm3)/1000000

Weight of required weld consumable in Kg = (274563 X 7.85)/1000000 = 2.155 Kgs

You can calculate ‘Single V’ in below weld consumable calculator from below by entering mentioned parameters

For Our other post please visit below links

- 𝐅𝐞𝐫𝐫𝐢𝐭𝐞 𝐓𝐞𝐬𝐭𝐢𝐧𝐠 𝐨𝐟 𝐒𝐭𝐚𝐢𝐧𝐥𝐞𝐬𝐬 𝐒𝐭𝐞𝐞𝐥𝐬

- METAL JOINING: BRAZING VS WELDING

- Hardness Testing: Definition, How It Works, Types, and Benefits

- Guide to Magnetic Particle Inspection (MPI)

- Submerged Arc Welding (SAW)

Pingback: 8 Most Common Welding Defects, Causes & Remedies - Welding Fabrication World

Pingback: Difference in EN ISO 10204 2.1, 2.2, 3.1 & 3.2 - Welding Fabrication World

Pingback: Welding Positions - Welding Fabrication World

Pingback: Mechanical Properties of Metals - Welding Fabrication World

Pingback: METAL JOINING: BRAZING VS WELDING - Welding Fabrication World

Sir,

Mass is equal to density x volume

Weight= mass x gravity

But in consumable calculator we consider weight = density x volume, sir pls explain