Welding Insights

Category Title: Welding Insights

Welcome to our Welding Insights category, your one-stop destination for a wealth of knowledge and resources dedicated to the art and science of welding. Whether you’re an experienced welder, a novice looking to learn, or a professional seeking the latest industry updates, this category is your gateway to all things welding.

Explore a diverse range of topics, from welding techniques and best practices to the latest advances in welding technology. Our expertly crafted articles, guides, and tutorials provide valuable insights that can enhance your welding skills and keep you up-to-date with industry trends.

What You’ll Find in Welding Insights:

Welding How-Tos: Discover step-by-step tutorials and expert tips on various welding processes, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW/TIG), gas metal arc welding (GMAW/MIG), and more. Learn the techniques that will help you create strong, reliable welds.

Welding Certifications: Dive into the world of welding qualification and certification. Understand the requirements for welder performance qualification (WPQ) and welding procedure qualification (WPQ). Stay informed about the latest updates in welding codes and standards.

Welding Safety: Safety is paramount in welding. Explore articles on protective gear, hazard awareness, and safe practices to ensure your well-being on the job.

Welding Inspections: Gain insights into non-destructive testing (NDT) methods, quality control, and welding inspection techniques. Learn how to identify and rectify common welding defects.

Welding Applications: Explore real-world applications of welding across industries, from aerospace and automotive to construction and manufacturing. Understand how welding plays a crucial role in building our world.

Welding Innovations: Stay ahead of the curve with updates on the latest welding technologies and innovations. Learn about cutting-edge equipment, automation, and digital tools that are shaping the future of welding.

Welding Community: Engage with fellow welders, share your experiences, and seek advice in our interactive forums and Q&A sections. Connect with a vibrant community of welding enthusiasts and professionals.

Whether you’re passionate about welding as a hobby or rely on it for your livelihood, our Welding Insights category is here to empower you with the knowledge and skills you need to excel in the world of welding. Join us on this journey of discovery and mastery, where the sparks truly fly, both figuratively and literally!

Welding is a critical process in numerous industries, from construction to automotive manufacturing. One of the key factors in achieving a successful weld is understanding the concept of polarity. In welding, polarity refers to the direction of current flow, which can significantly impact the quality and characteristics of the weld. This article will explore the […]

Ferrite testing, also known as a ferritescope test, is a fast and non-destructive inspection technique used to measure delta ferrite levels in austenitic stainless steel and duplex stainless steel materials. Maintaining the correct ferrite content is crucial for ensuring corrosion resistance, durability, and preventing cracks in the material. Exceeding the maximum allowable ferrite content can

There are several methods available for joining metals, including welding, brazing and soldering. What is the difference between welding and brazing? What is the difference between brazing and soldering? Let’s explore the distinctions plus comparative advantages as well as common applications. This discussion will deepen your understanding of metal joining and help you identify the

Hardness refers to the resistance of a material to deformation, particularly when subjected to various forms of external forces like compression, indentation, scratching, or abrasion. It’s an essential mechanical property that indicates the material’s ability to withstand such forces without undergoing permanent deformation or damage. Hardness is influenced by factors such as the material’s composition,

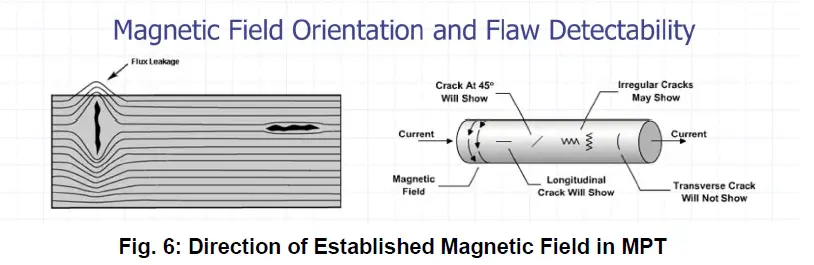

Magnetic Particle Inspection (MPI) stands as a crucial nondestructive testing process utilized to detect surface and shallow subsurface discontinuities in ferromagnetic materials. These materials encompass iron, nickel, cobalt, and certain alloys susceptible to magnetization. The method involves establishing a magnetic field within the test object, achieved through direct or indirect magnetization. Direct magnetization passes electric

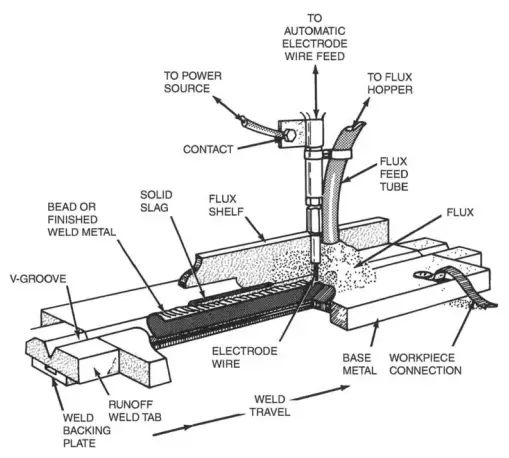

Submerged arc welding (SAW) is a proficient welding technique that employs a continuous feed of tubular electrode to fuse two metals by generating heat through the interaction between the electrode and the metal. To shield the arc and molten zone from atmospheric contaminants, the welding process submerges them beneath a protective layer of granular flux.

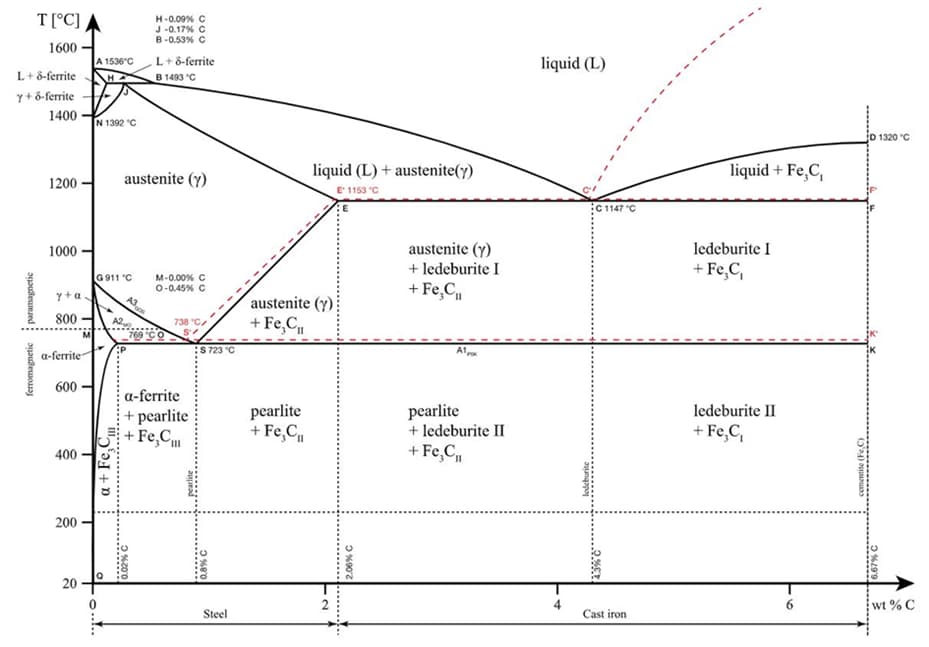

Steel, a fundamental material in modern industrial applications, owes its versatility and performance to the careful inclusion of various alloying elements. Alloying elements are introduced to steel to alter its properties, enhancing its strength, durability, corrosion resistance, and other crucial characteristics. Steels are manufactured by combining iron with carbon, a process integral to steelmaking. The

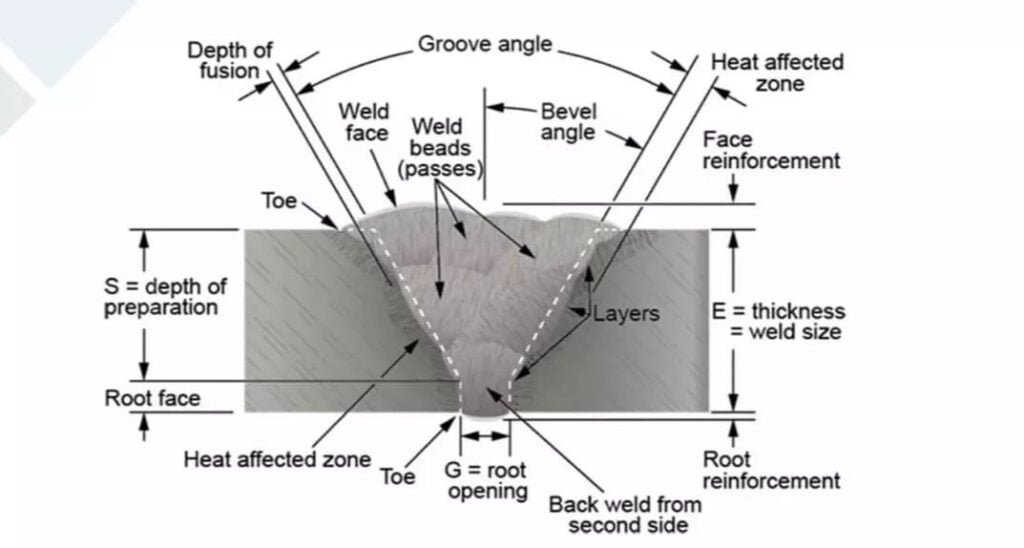

Welding, a fundamental process in metal fabrication and construction, involves joining metal components through the application of heat and pressure. Two common types of welds, butt and fillet welds, are integral in creating strong, durable joints. Understanding nomenclature and components of Butt and Fillet Welds is crucial for welders and engineers to ensure the integrity

“Varieties of Electrodes and Their Constituents” There is a wide array of manual metal arc (MMA) electrodes available, grouped into three categories based on their primary flux component: cellulosic, rutile, and basic. These electrodes typically consist of a core wire, usually 2.5–6mm in diameter, coated with flux. The core wire is commonly crafted from low-quality

Porosity formation within aluminium welding arises from the entrapment of gases in the molten weld pool, unable to escape before solidification. The chief concern is hydrogen, sourced from contaminants like hydrocarbons (e.g., grease, skin oils) or moisture, breaking down within the arc plasma to generate atomic hydrogen. Hydrogen readily dissolves in molten aluminium but exhibits