Welding Insights

Category Title: Welding Insights

Welcome to our Welding Insights category, your one-stop destination for a wealth of knowledge and resources dedicated to the art and science of welding. Whether you’re an experienced welder, a novice looking to learn, or a professional seeking the latest industry updates, this category is your gateway to all things welding.

Explore a diverse range of topics, from welding techniques and best practices to the latest advances in welding technology. Our expertly crafted articles, guides, and tutorials provide valuable insights that can enhance your welding skills and keep you up-to-date with industry trends.

What You’ll Find in Welding Insights:

Welding How-Tos: Discover step-by-step tutorials and expert tips on various welding processes, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW/TIG), gas metal arc welding (GMAW/MIG), and more. Learn the techniques that will help you create strong, reliable welds.

Welding Certifications: Dive into the world of welding qualification and certification. Understand the requirements for welder performance qualification (WPQ) and welding procedure qualification (WPQ). Stay informed about the latest updates in welding codes and standards.

Welding Safety: Safety is paramount in welding. Explore articles on protective gear, hazard awareness, and safe practices to ensure your well-being on the job.

Welding Inspections: Gain insights into non-destructive testing (NDT) methods, quality control, and welding inspection techniques. Learn how to identify and rectify common welding defects.

Welding Applications: Explore real-world applications of welding across industries, from aerospace and automotive to construction and manufacturing. Understand how welding plays a crucial role in building our world.

Welding Innovations: Stay ahead of the curve with updates on the latest welding technologies and innovations. Learn about cutting-edge equipment, automation, and digital tools that are shaping the future of welding.

Welding Community: Engage with fellow welders, share your experiences, and seek advice in our interactive forums and Q&A sections. Connect with a vibrant community of welding enthusiasts and professionals.

Whether you’re passionate about welding as a hobby or rely on it for your livelihood, our Welding Insights category is here to empower you with the knowledge and skills you need to excel in the world of welding. Join us on this journey of discovery and mastery, where the sparks truly fly, both figuratively and literally!

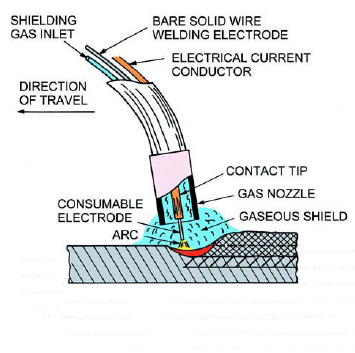

Gas Metal Arc Welding (GMAW), commonly known as MIG (Metal Inert Gas) or MAG (Metal Active Gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode and the workpiece metal. This arc generates intense heat, causing the workpiece metal to melt and fuse […]

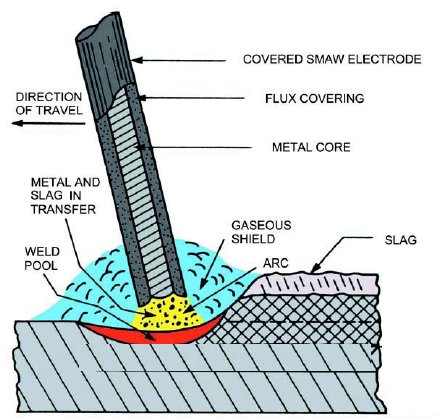

Introduction Shielded Metal Arc Welding (SMAW), commonly known as stick welding, is a pivotal manual arc welding process. It employs a consumable electrode enveloped in a flux to fuse metals together. Renowned for its versatility and simplicity, SMAW has earned its place as one of the most widely used welding techniques globally. This comprehensive guide

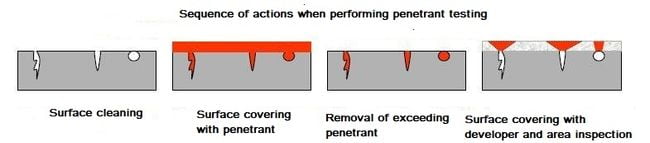

In the world of non-destructive testing (NDT), dye penetrant testing is a widely employed method for detecting surface-breaking defects in various materials, including metals, plastics, and ceramics. This technique, often referred to as liquid penetrant inspection or simply penetrant testing, plays a crucial role in ensuring the structural integrity and safety of a wide range

Hydrogen cracking, also known as hydrogen-induced cracking or HIC, is a common concern in various industries, particularly in the field of metalworking, welding, and construction. This phenomenon occurs when hydrogen atoms infiltrate the microstructure of a metal, causing it to become brittle and prone to cracking. Understanding the common causes and effective cures for hydrogen

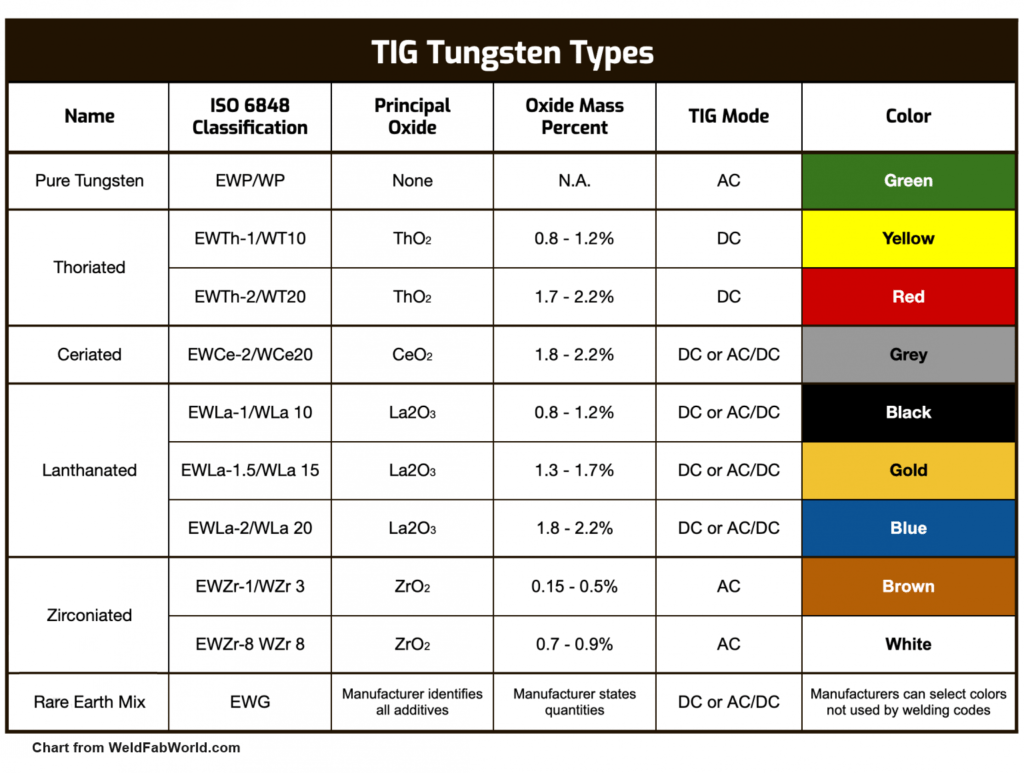

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is a highly precise and versatile welding process used in various industries. One of the key components in TIG welding is the tungsten electrode. These electrodes come in various types, each designed for specific applications and materials. In this article, we will

Gas Tungsten Arc Welding (GTAW), also known as TIG welding, is a captivating combination of science and craftsmanship. It is considered one of the most precise and versatile methods in the welding industry, capable of producing flawless and superior welds in different materials. In this blog, we will explore the fundamental principles, necessary equipment, essential

A stress-strain curve is a visual representation illustrating how a material behaves under increasing loads. Stress, which is the ratio of force to cross-sectional area, and strain, the ratio of a change in dimension length to the original length, are the defining factors in this graph. These curves can be constructed to examine how materials

The ASME B31.1 – 2022 Power Piping Code plays a pivotal role in ensuring the integrity and safety of power piping systems. One crucial aspect of this code is the meticulous examination and testing of welds to ascertain their quality and structural soundness. In this article we will discuss about visual examination as per Chapter

Welding is a crucial skill in various industries, and these books can be valuable resources for professionals looking to enhance their expertise. Here’s a list of the top 10 welding books by Indian authors along with brief explanations for each: See Best 10 books for welding by any authors 1. “Welding Technology” by Dr. R.

Welding, often referred to as the “welding arts,” is a highly specialized craft that demands a relentless pursuit of knowledge and expertise. Whether you’re an experienced welding professional seeking to elevate your skills or a budding expert aiming to refine your craft, the right books can be invaluable allies on your journey. In this article,