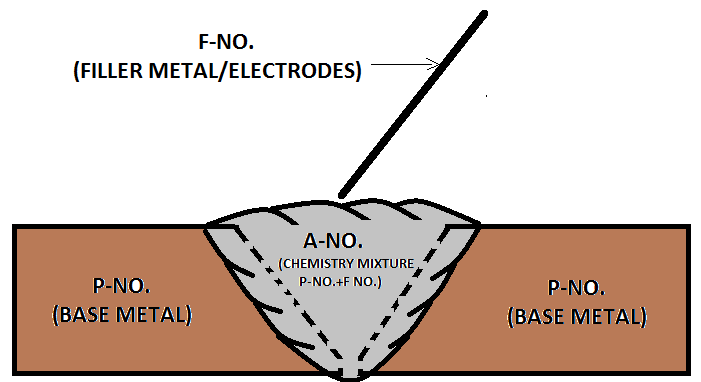

P-Number, Group No, F-Number and A-Number in welding (ASME Section IX)

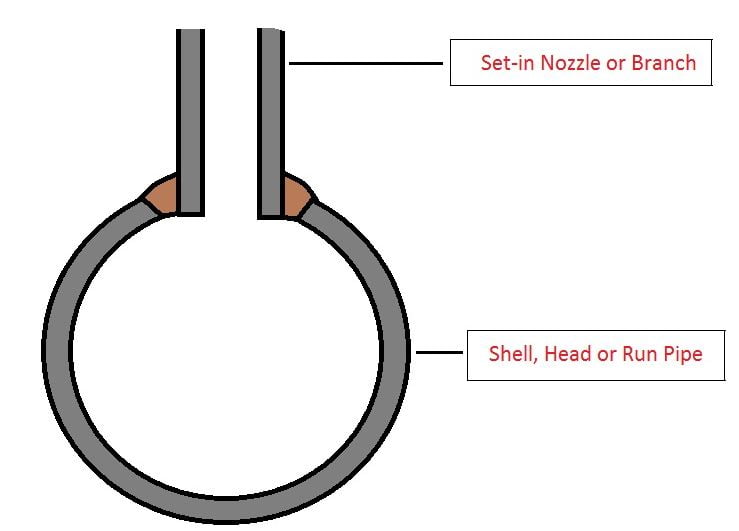

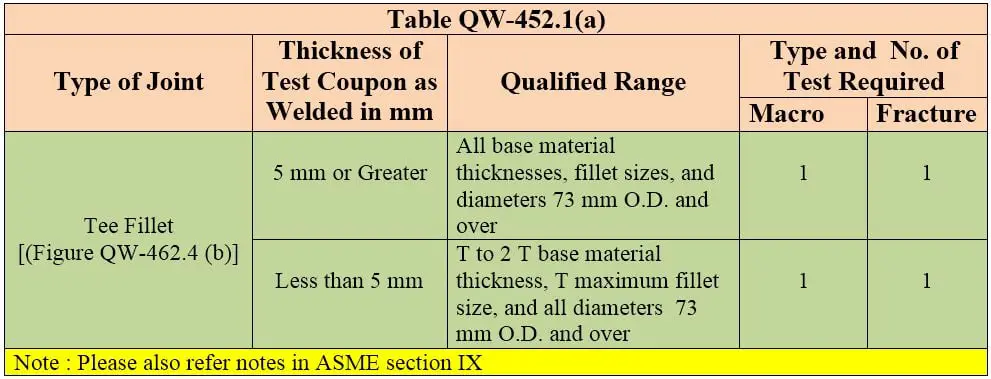

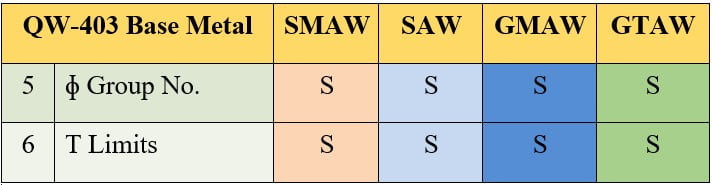

ASME Boiler and pressure vessel code (BPVC) Section IX has assigned certain numbers to base metals to minimize the number of procedure and qualifications these are P-Number, Group No, F-Number and A-Number in welding. Base metals are categorized as P number is further divided in group numbers based essentially on comparable base metal characteristics, such […]