When weld defects form in a weld they can weaken the joint. In some cases, this results in complete failure of the weldment. In serious cases, there can be severe consequences to a failing weld. So, you need to understand the various common welding defects. But in addition, you must know how to prevent them from happening. Some are visual welding defects and some are volumetric.

What is a weld defect?

A weld defect is one or more flaw or imperfections in the weld that compromises the indented use of a weldment.

Flaw or imperfections in the weld is called discontinuity. Discontinuities which exceeds the acceptable limits are classified as weld defects.

Defect in welding have negative effects on the quality, strength and reliability of welded joints.

It is crucial to detect, identify and rectify welding defects through proper inspection, testing and adherence to control measures. Employing skilled welders, using appropriate welding techniques, and implementing rigorous quality assurance procedures can help minimize the occurrence of defects and their associated negative effects.

We all want defects shall not occur and welds shall not be rejected. So, you need to know the types of the defects that can occur during welding and how to avoid them.

Apple iPhone 13 (128GB) – Midnight

₹49,300.00 (as of 12/07/2024 13:41 GMT +05:30 – More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)realme NARZO 70x 5G (Ice Blue, 6GB RAM,128GB Storage)|120Hz Ultra Smooth Display|Dimensity 6100+ 6nm 5G|50MP AI Camera|45W Charger in The Box

₹13,498.00 (as of 12/07/2024 13:41 GMT +05:30 – More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Common Welding Defects with Remedies

There are many types of arc welding defects, but in general, the most common weld defects are:

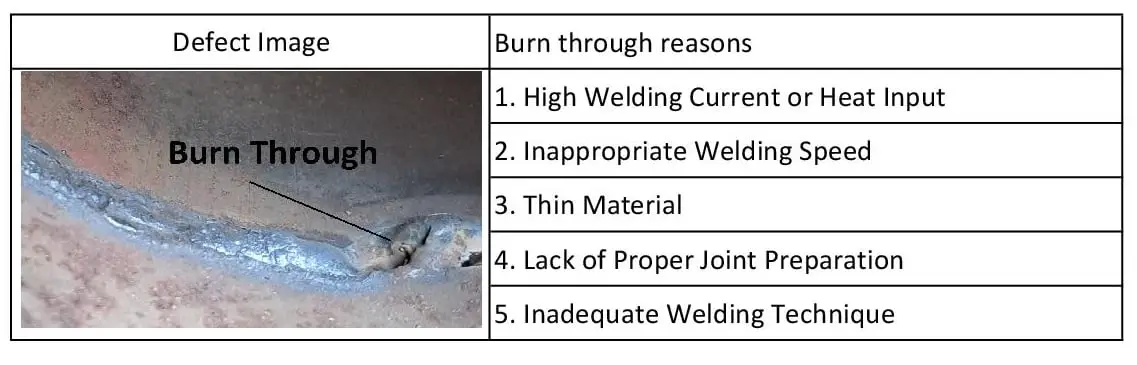

Burn Through :

“Burn through” in welding refers to a situation where excessive heat and welding parameters cause a hole or penetration through the base metal being welded. It occurs when the welding process generates more heat than required for the thickness and type of material being joined. This excessive heat melts the base metal, creating a hole or opening that can compromise the structural integrity of the weld joint.

Burn through can occur for several reasons and have to control these parameter

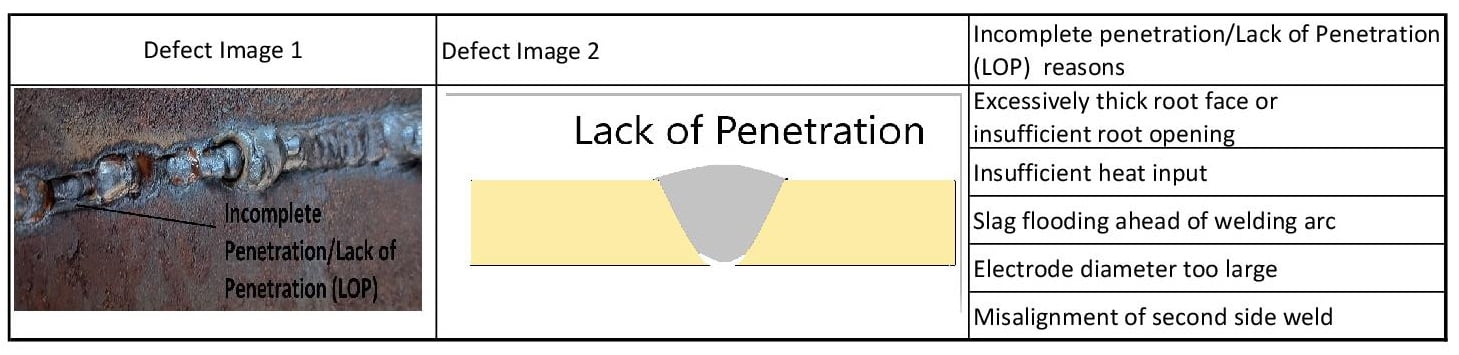

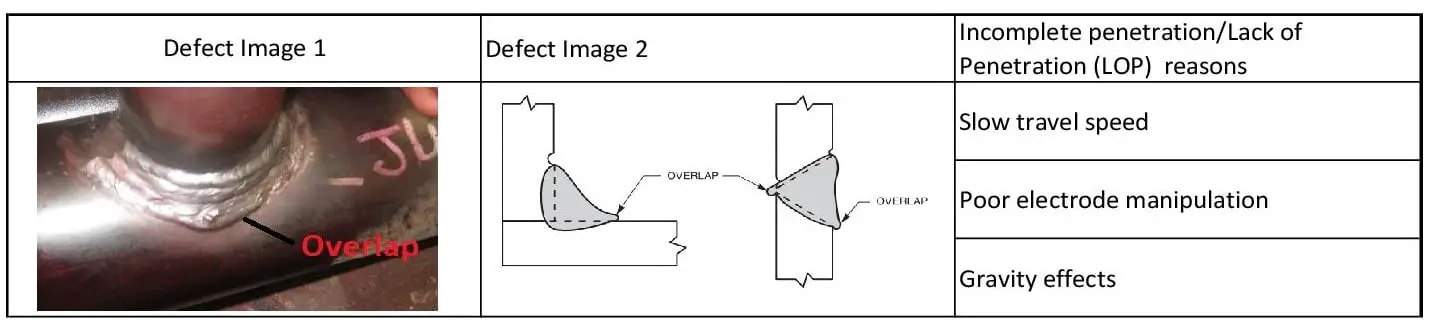

Incomplete penetration/Lack of Penetration (LOP) :

Incomplete penetration in welding refers to a situation where the weld bead does not fully penetrate into the joint, leaving a gap or an unfused portion between the weld metal and the base metal. “A joint root condition in a groove weld in which weld metal does not extend through the joint thickness.”

Lack of Fusion can cause due to various factors

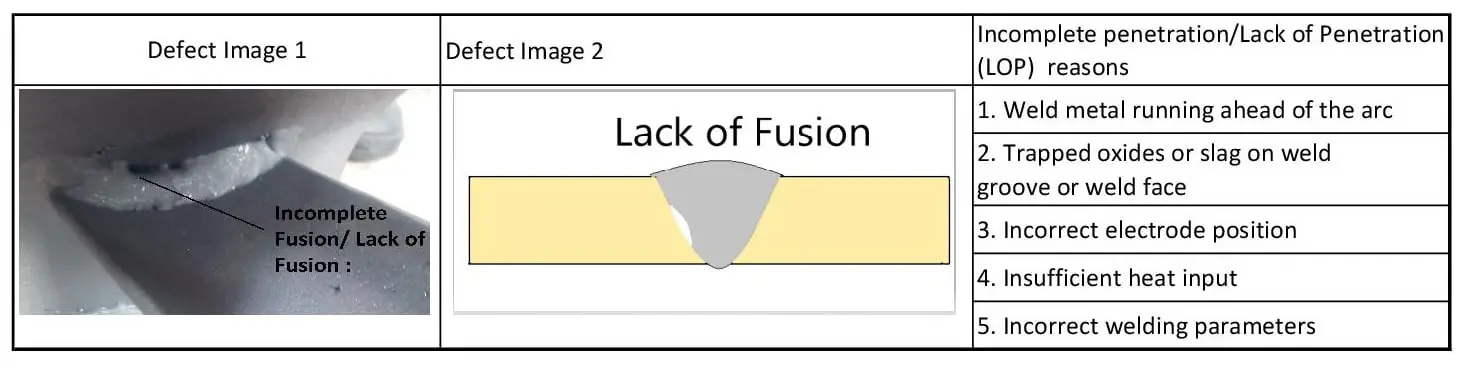

Incomplete Fusion/ Lack of Fusion :

Incomplete fusion, often referred to as “Lack of Fusion” (LOF) in welding, occurs when the weld metal does not properly fuse with the base metal or with the previously deposited weld metal. This results in a gap or an unfused area between the two materials, compromising the strength and integrity of the weld joint.

Incomplete Fusion can occur due to various factors

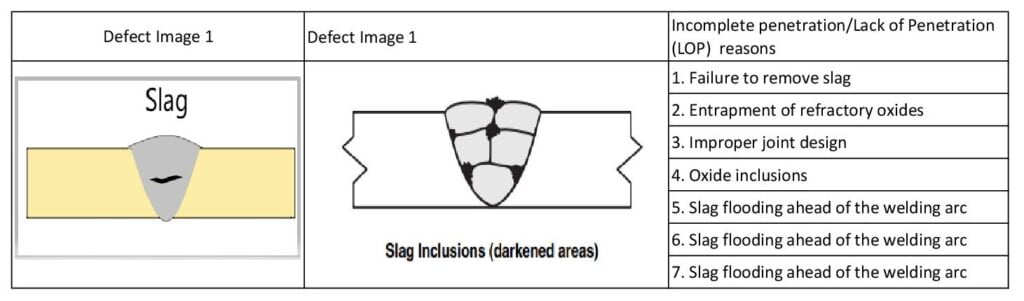

Inclusions (Slag/Tungsten) :

Inclusions are defined as “Entrapped foreign solid material, such as slag, flux, tungsten, or oxide.” The inclusions may be found as single particles, aligned particles, or clustered particles. Slag inclusions are frequently found on the weld surfaces, or along the toes of the weld due to improper cleaning techniques. Tungsten inclusions are usually subsurface. Examples of inclusions are shown below. Inclusions on the surface can be detected by VT; subsurface inclusions require UT or RT.

“Tungsten inclusion” specifically refers to a type of defect that can occur in Tungsten Inert Gas (TIG) or Gas Tungsten Arc Welding (GTAW). Tungsten is used as the electrode in TIG welding, and if small particles of the tungsten electrode break off during the welding process, they can become trapped within the weld bead, leading to a tungsten inclusion. This can result in reduced weld quality and structural integrity.

Inclusions (Slag/Tungsten) can occur due to various factors

Cracks :

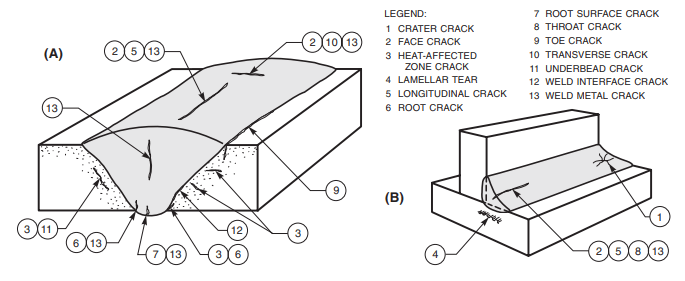

A crack is defined as “A fracture type discontinuity characterized by a sharp tip and a high ratio of length and width to opening displacement.” Cracks are usually considered the most severe discontinuity because of their tendency to propagate under stress. Cracks are usually further described by their location geometry, time of occurrence, or common usage terms; see figure below for AWS crack terminology.

Types of Weld Cracks

Types of cracks often include the following prefixes: base metal, cold, crater, delayed, face, heat-affected zone,

hot cracking, hydrogen, intergranular, lamellar tear, longitudinal, quench, root, service induced, stress corrosion, throat,

toe, transgranular, transverse, underbead, weld metal, and others.

Cracks can occur due to various factors

| Causes: Weld Metal Cracking | Remedies: Weld Metal Cracking |

| Highly rigid joint | Preheat Relieve residual stresses mechanically (peening) Minimize shrinkage stresses using backstep or block welding sequence |

| Excessive dilution | Change welding current and travel speed Weld with covered electrode negative; butter the joint faces prior to welding |

| Defective electrodes | Change to new electrode; bake electrodes to remove moisture |

| Poor fit-up | Reduce root opening; build up the edges with weld metal. Increase root opening. |

| Small weld bead | Increase electrode size; raise welding current; reduce travel speed |

| High sulfur base metal | Use filler metal low in sulfur |

| Angular distortion | Change to balanced welding on both sides of joint |

| Crater cracking | Fill crater before extinguishing the arc; use a welding current decay device when terminating the weld bead |

| Causes: Heat-Affected Zone | Remedies: Heat-Affected Zone |

| Hydrogen in welding atmosphere | Use low-hydrogen welding process; preheat and hold for 2 hour after welding or postweld heat treat immediately |

| Hot cracking | Use low heat input; deposit thin layers; change base metal and/or filler metal |

| Low ductility | Use preheat; anneal base metal prior to welding |

| High residual stresses | Redesign weldment; change welding sequence; apply intermediate stress-relief heat treatment |

| High hardenability | Preheat; increase heat input; heat treat without cooling to room temperature |

| Brittle phases in the microstructure | Solution heat treat prior to welding |

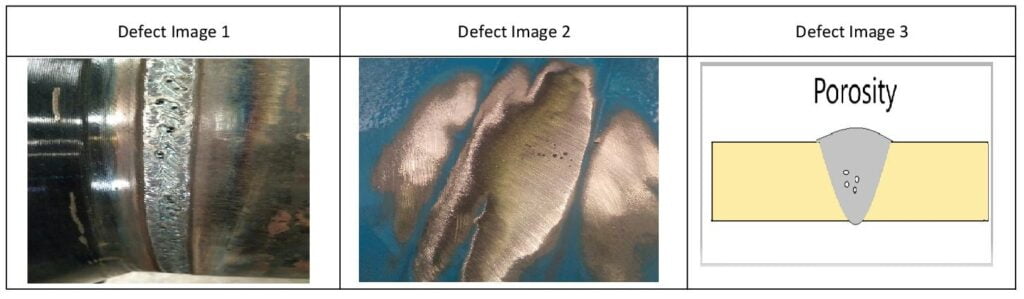

Porosity :

Porosity is defined as “Cavity-type discontinuities formed by gas entrapment during solidification or in a

thermal spray deposit.” The porosity may be surface or subsurface, a single cavity, aligned, or clustered, and is represented by the following figures.

| Causes | Remedies |

| Excessive hydrogen, nitrogen, or oxygen in welding atmosphere | Use low-hydrogen welding process; filler metals high in deoxidizers; increase shielding gas flow |

| High solidification rate | Use preheat or increase heat input |

| Dirty base metal | Clean joint faces and adjacent surfaces |

| Dirty filler wire | Use specially cleaned and packaged filler wire, and store it in clean area |

| Improper arc length, welding current, or electrode manipulation | Change welding conditions and techniques |

| Volatization of zinc from brass | Use copper-silicon filler metal; reduce heat input |

| Galvanized steel | Remove zinc prior to welding Use E6010 electrodes and manipulate the arc heat to volatilize the zinc ahead of the molten weld pool |

| Excessive moisture in electrode covering or on joint surfaces | Use recommended procedures for baking and storing electrodes Preheat the base metal |

| High sulfur base metal | Use electrodes with basic slagging reactions |

Overlap Welding Defect :

Overlap is defined as “The protrusion of weld metal beyond the weld toe or weld root.” Examples are shown

below for fillet and groove welds.

Detection of overlap is usually found by VT if the surfaces are visible to the eye; oblique lighting and 10x magnification are helpful. PT and MT may be required to inspect questionable areas.

Undercut Welding Defect :

Undercut is defined as “A groove melted into the base metal adjacent to the weld toe or weld face and left

unfilled by weld metal.“

Detection of surface undercut is easily found by VT using oblique lighting. ‘Catching a thumbnail’ in the undercut groove is also helpful in its detection. Internal undercut on groove welds where access to the root is not possible requires UT or RT methods.

12 Most Common Welding Discontinuities & Defects by Welding intro

Download PDF, weld defects PPT, and images from Link

Weld Consumable Excel Calculator Download Link

Weld Consumable Calculation PPT Free Download For Training

Welding Symbols PPT Free Download For Training

Welding joint and symbols guide PDF of 96 pages

Thanks for visiting if want to Visit our more articles from below links

Thickness Qualification Range for PQR and WPQ

P-Number, Group No, F-Number and A-Number in welding (ASME Section IX)

Mechanical Testing Requirement as per ASME BPVC Section IX

Weld Consumable Calculation for “Single V Groove joint”

- 𝐅𝐞𝐫𝐫𝐢𝐭𝐞 𝐓𝐞𝐬𝐭𝐢𝐧𝐠 𝐨𝐟 𝐒𝐭𝐚𝐢𝐧𝐥𝐞𝐬𝐬 𝐒𝐭𝐞𝐞𝐥𝐬

- METAL JOINING: BRAZING VS WELDING

- Hardness Testing: Definition, How It Works, Types, and Benefits

- Guide to Magnetic Particle Inspection (MPI)

- Submerged Arc Welding (SAW)

Pingback: Non-Destructive Testing Methods - Welding Fabrication World

Pingback: What is Welding Porosity? Causes, Prevention & Fixes - Welding Fabrication World

Pingback: Acceptance criteria for visual examination as per B31.1 - Welding Fabrication World

Pingback: What Is Hot Cracking (Solidification Cracking)? - Welding Fabrication World

Pingback: Shielded Metal Arc Welding (SMAW): The Complete Guide

Pingback: Guide to Magnetic Particle Inspection (MPI) - Welding Fabrication World