A Mill Test Certificate (MTC) or Mill Test Report is issued by a manufacture/supplier to certify the chemical and mechanical properties of a material/product/welding consumable and its compliance to the applicable forms, technical specifications and standards. The MTC may contain all specification of the product including weight, dimensions, chemical composition, mechanical properties, condition of heat treatment, traceability, test results, manufacturing process. Generally mill test certificates are required with conformance of EN 10204.

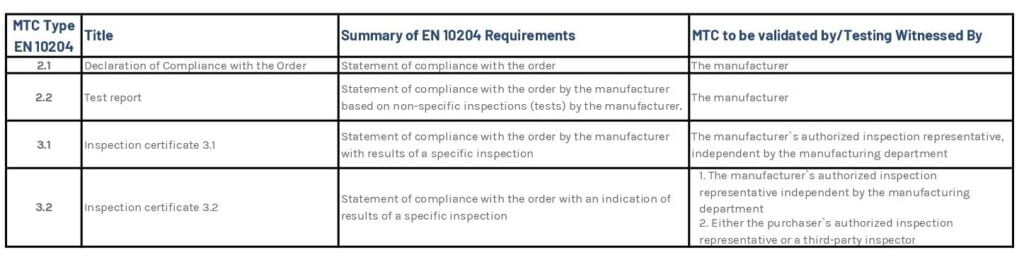

This is a standard that specifies requirements for the inspection and testing of metallic products. The differences between the various types of inspection certificates defined by ISO 10204 are as follows:

- EN ISO 10204 2.1: This type of certificate simply states that the products supplied are in compliance with the requirements of the order, but no specific testing or inspection results are provided.

- EN ISO 10204 2.2: This certificate states that the products supplied have been tested by the manufacturer in accordance with specific procedures and that the results of these tests meet the requirements of the order.

- EN ISO 10204 3.1: This type of certificate states that the products supplied have been inspected and tested by an inspection agency of manufacturer independent by the manufacturing department , and that the results of these tests meet the requirements of the order.

- EN ISO 10204 3.2: This certificate is similar to the 3.1 certificate, but witnessed by The manufacturer`s authorized inspection representative independent by the manufacturing department and Either the purchaser`s authorized inspection representative or a third-party inspector.

In summary, the differences between the various types of EN ISO 10204 certificates are based on the level of testing and inspection performed, and the involvement of independent third-party inspection agencies.

Visit our other articles from below links

| Thickness Qualification Range for PQR and WPQ | Weld Consumable Calculation for “Single V Groove joint” | Welding Positions | P91 Material Welding Requirement |

Tools Excels & PPTs