In industrial and protective coatings, maintaining surface integrity is critical to ensuring both long-term performance and aesthetic quality. Coatings act as a barrier against environmental factors such as moisture, UV radiation, and chemicals, while also improving the appearance of materials. However, when defects occur, they compromise not just the look but also the durability, protection, and safety of the coated structure.

Understanding coating defects—their types, root causes, and associated challenges—is essential for industries like oil & gas, construction, marine, automotive, and infrastructure where coatings play a decisive role in asset protection and corrosion control.

🎨 Common Coating Defects & Their Causes

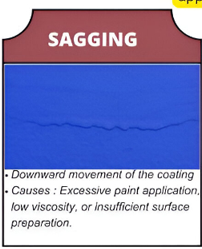

1. Sagging

- Description: A downward movement of the coating film, resulting in an uneven and dripped appearance.

- Causes:

- Excessive paint application

- Low paint viscosity

- Insufficient or uneven surface preparation

- Challenge: Sagging not only affects aesthetics but also creates thin spots that compromise protection.

2. Blistering

- Description: Formation of bubbles or blisters under the paint film.

- Causes:

- Moisture entrapment

- Coating over a contaminated or hot surface

- Inadequate surface cleaning

- Challenge: Blisters weaken adhesion and often lead to peeling, exposing bare metal to corrosion.

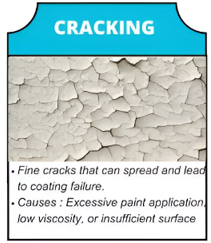

3. Cracking

- Description: Fine cracks in the coating that can spread and result in complete coating failure.

- Causes:

- Excessive film thickness

- Low viscosity of coating

- Poor or improper surface preparation

- Challenge: Once cracking starts, corrosion progresses rapidly through exposed pathways.

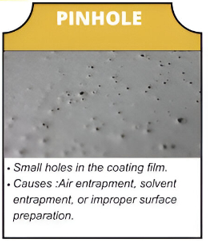

4. Pinhole Formation

- Description: Small holes resembling pin pricks in the coating film.

- Causes:

- Air or solvent entrapment

- Improper surface preparation

- Application in high humidity environments

- Challenge: Pinholes may appear minor but serve as entry points for moisture and chlorides, accelerating underfilm corrosion.

5. Flash Rusting

- Description: Rust formation shortly after surface preparation, even before coating application.

- Causes:

- High humidity conditions

- Waterborne cleaning without immediate recoating

- Challenge: Flash rust significantly reduces adhesion and leads to premature coating failure.

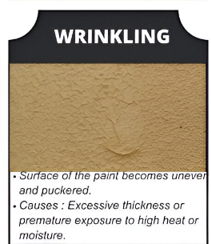

6. Wrinkling

- Description: Surface of the paint becomes uneven and puckered.

- Causes:

- Application of excessively thick coatings

- Premature exposure to heat or moisture before curing

- Challenge: Wrinkled surfaces trap contaminants and moisture, leading to faster breakdown.

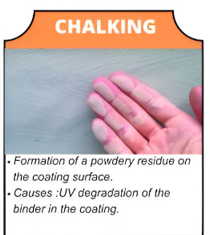

7. Chalking

- Description: Formation of a powdery residue on the surface of the coating.

- Causes:

- UV degradation of the binder in the coating

- Challenge: Though primarily aesthetic, chalking can indicate binder breakdown and eventual erosion of protective layers.

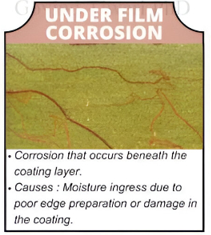

8. Underfilm Corrosion

- Description: Corrosion occurring beneath the coating, often unnoticed until severe damage is done.

- Causes:

- Moisture ingress due to poor edge preparation

- Damage in coating film

- Challenge: This defect is particularly dangerous as it spreads beneath the film, often requiring complete recoating or substrate replacement.

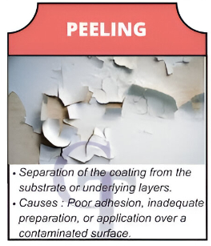

9. Peeling

- Description: Detachment of the coating film from the substrate or underlying layers.

- Causes:

- Poor adhesion

- Contaminated surface

- Inadequate preparation before application

- Challenge: Peeling exposes large substrate areas, leading to rapid corrosion and loss of protective function.

⚠️ Challenges in Managing Coating Defects

Even with high-performance coatings, industries face several challenges:

- Early Detection: Identifying defects before they become severe can be difficult, especially for underfilm corrosion.

- Environmental Control: Temperature, humidity, and airborne contaminants during application must be carefully managed.

- Surface Preparation: Most defects originate from poor preparation, yet this step is often rushed due to time or cost constraints.

- Material Selection: Choosing the wrong coating system for the environment leads to premature degradation.

- Operational Balance: Industries must balance speed, cost, and quality — a tough challenge in high-pressure projects.

🔍 Key Takeaways

- Surface preparation is everything – over 70% of coating failures are linked to inadequate preparation.

- Environmental control during application drastically reduces risks like blistering, wrinkling, and flash rusting.

- The right product for the right environment ensures maximum durability.

- Training and awareness among applicators and inspectors are critical to reduce costly rework.

- Regular inspections and maintenance extend coating life and safeguard asset integrity.

Conclusion

Coating defects, while common, are preventable through proper surface preparation, environmental control, and correct application techniques. By understanding the causes and challenges of defects like sagging, blistering, cracking, or peeling, industries can minimize rework costs, extend service life, and ensure safety. Ultimately, a coating is only as strong as its weakest point, making vigilance and discipline in every step of the process essential.

✅ This article highlights the importance of coating defect awareness for industries committed to long-term performance and corrosion control.