In industries such as Oil & Gas, Power, Marine, and Infrastructure, coatings are not just for appearance — they are a shield against corrosion, chemical attack, UV exposure, and harsh environmental conditions.

However, even the best coating system can fail if the surface is not properly prepared, the environment is unsuitable, or the coating is applied incorrectly.

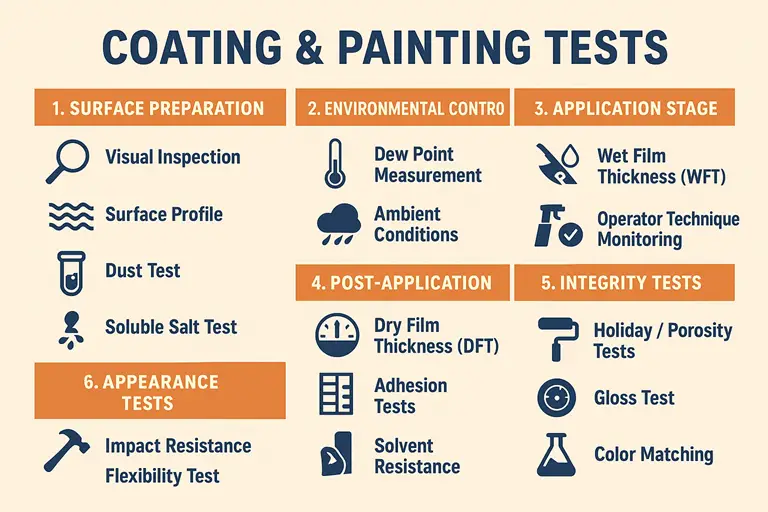

That’s why Coating and Painting Tests form the backbone of corrosion protection programs, ensuring every layer performs as intended throughout its life cycle.

Let’s explore these tests — their purpose, method, and practical importance — across each stage of coating application.

1. Surface Preparation – Foundation of Coating Success

Before applying paint, the steel surface must be perfectly prepared. Surface contaminants like rust, grease, dust, or salts can prevent adhesion and lead to premature failure.

Visual Inspection

Purpose: To verify the substrate is clean, free from rust, oil, grease, moisture, or old paint.

Explanation: Performed before blasting and coating using direct visual checks or white cloth tests.

Standards: ISO 8501-1, SSPC standards.

Why It Matters: A single oil stain can prevent adhesion, leading to coating blistering or delamination.

Surface Profile (Anchor Pattern)

Purpose: To ensure sufficient surface roughness for the coating to mechanically “grip” the steel.

Explanation: Measured using replica tape (Testex), comparators, or stylus gauge.

Standards: ASTM D4417, ISO 8503.

Typical Range: 40–75 µm for epoxy coatings.

Why It Matters: Proper roughness ensures bonding strength and coating longevity.

Dust Test

Purpose: To check residual dust after blasting, which can prevent coating adhesion.

Explanation: A clear adhesive tape is pressed to the surface and compared with ISO dust rating charts.

Standards: ISO 8502-3.

Why It Matters: Dust particles can create weak points and cause premature coating failure.

Soluble Salt Test

Purpose: To detect chloride and sulfate contamination after blasting.

Explanation: Uses the Bresle patch method or conductivity meter.

Standards: ISO 8502-6/9, NACE SP0508.

Acceptance: Typically ≤ 20 µg/cm².

Why It Matters: Salts attract moisture, leading to corrosion under the coating film (osmotic blistering).

2. Environmental Control – Right Conditions, Right Results

Coating should only be applied under suitable environmental conditions. Humidity, temperature, and condensation can ruin even perfect surface preparation.

Dew Point Test

Purpose: To ensure no condensation forms on the surface during coating.

Explanation: Dew point meters measure ambient and steel temperature.

Standard: ISO 8502-4.

Requirement: Steel must be ≥ 3°C above dew point.

Why It Matters: Moisture on the surface traps air and causes pinholes or poor adhesion.

Ambient Condition Monitoring

Purpose: To confirm humidity, temperature, and wind speed are within acceptable limits.

Explanation: Measured with a hygrometer and anemometer before and during coating.

Standard: ISO 8502-4, ASTM D3276.

Why It Matters: High humidity (>85%) can delay curing and cause coating blushing.

3. Application Stage – Getting the Film Right

During coating application, thickness and uniformity must be controlled for performance and appearance.

Wet Film Thickness (WFT)

Purpose: To verify the correct film build during application.

Explanation: Measured with a wet film comb or gauge immediately after spraying.

Formula: DFT = WFT × (% solids by volume).

Standard: ASTM D4414.

Why It Matters: Ensures correct dry film thickness after curing, avoiding thin spots or over-application.

Application Technique Monitoring

Purpose: To ensure uniform spray pattern and overlap.

Explanation: Visual monitoring of painter’s spray angle, speed, and overlap.

Why It Matters: Prevents runs, sags, or uneven film buildup.

4. Post-Application Tests – Ensuring Quality After Curing

Once coating is cured, it must be verified for correct thickness, adhesion, and curing completeness.

Dry Film Thickness (DFT)

Purpose: To confirm the final film thickness meets specification.

Explanation: Measured using magnetic or electronic gauges.

Standards: ASTM D7091, ISO 2178, ISO 2360.

Typical Range: 250 ± 25 μm.

Why It Matters: Too thin = poor protection; too thick = cracking or solvent entrapment.

Adhesion Test – Cross-Cut

Purpose: To evaluate adhesion of thin coatings (<250 μm).

Explanation: A grid pattern is cut through the coating and tape is applied/removed.

Standard: ISO 2409.

Acceptance: Rating 0–1 = excellent adhesion.

Adhesion Test – Pull-Off

Purpose: To measure bond strength between coating and substrate.

Explanation: A dolly is glued to the surface and pulled until detachment.

Standards: ASTM D4541, ISO 4624.

Acceptance: ≥ 5 MPa for epoxy coatings.

Why It Matters: Ensures coating won’t delaminate under stress.

Solvent Resistance (Cure Test)

Purpose: To check the degree of curing.

Explanation: MEK rub test with cotton swab soaked in methyl ethyl ketone.

Standard: ASTM D4752.

Acceptance: ≥ 4 double rubs without failure.

Why It Matters: Under-cured coatings have poor chemical and abrasion resistance.

Hardness Test

Purpose: To assess mechanical strength of cured film.

Explanation: Using pencil hardness, Barcol, or Shore durometer.

Standards: ASTM D3363, ASTM D2583.

Why It Matters: Indicates coating’s resistance to damage during handling or service.

5. Integrity Tests – Detecting Hidden Defects

Holiday / Porosity Test (Low Voltage)

Purpose: To detect pinholes and holidays in thin coatings (<500 μm).

Explanation: A wet sponge tester passes over the surface; if moisture reaches the substrate, an alarm sounds.

Standard: ASTM D5162 (Method A).

Why It Matters: Even a single pore can initiate corrosion beneath the coating.

Holiday / Porosity Test (High Voltage)

Purpose: For detecting discontinuities in thick linings (>500 μm).

Explanation: Spark tester applies voltage; sparks indicate coating defects.

Standards: ASTM D5162 (Method B), NACE SP0188.

Why It Matters: Essential for linings in tanks, pipelines, and buried structures.

6. Appearance Tests – Aesthetic & Functional Checks

Gloss Test

Purpose: To measure the reflective property of the coating surface.

Explanation: Gloss meter measures light reflection at specified angles.

Standard: ASTM D523.

Why It Matters: Ensures coating meets visual or branding requirements.

Color Matching

Purpose: To confirm coating color matches approved standards.

Explanation: Measured by spectrophotometer or compared visually under controlled lighting.

Standards: ASTM D1729, ISO 3668.

Why It Matters: Especially important in architectural and visible structures for consistency.

7. Durability & Performance Tests – Proving Long-Term Reliability

Impact Resistance Test

Purpose: To assess coating toughness and flexibility under sudden force.

Explanation: Falling weight test determines the ability to resist cracking.

Standard: ASTM D2794.

Flexibility Test

Purpose: To check if coating can bend without cracking.

Explanation: Conducted on conical mandrel or bend test equipment.

Standards: ASTM D522, ISO 1519.

Abrasion Resistance Test

Purpose: To evaluate coating’s resistance to wear and rubbing.

Explanation: Taber abrasion test measures weight loss after set revolutions.

Standard: ASTM D4060.

Chemical Resistance Test

Purpose: To confirm coating’s resistance to acids, alkalis, and solvents.

Explanation: Spot/immersion tests in specified chemicals.

Standard: ASTM D1308.

Accelerated Weathering Test

Purpose: To simulate UV exposure, condensation, and aging.

Explanation: QUV chamber (UV-A, UV-B lamps) cycles light and moisture.

Standards: ASTM G154, ASTM G155.

Salt Spray Test

Purpose: To simulate corrosive marine or industrial environments.

Explanation: Continuous salt fog chamber exposure.

Standards: ASTM B117, ISO 9227.

Why It Matters: Predicts coating performance in coastal or offshore conditions.

Cyclic Corrosion Test

Purpose: To replicate alternating wet/dry environments for realistic corrosion simulation.

Explanation: Alternating salt spray and drying cycles.

Standard: ISO 11997-1.

Why These Tests Matter

A coating is only as strong as the inspection that verifies it.

By following ASTM, ISO, NACE, and SSPC standards, QA/QC teams ensure:

Long-lasting corrosion protection

Reduced maintenance costs

Improved safety and reliability

Compliance with project specifications (Aramco, ADNOC, Shell DEP, SABIC, etc.)

FAQs on Coating & Painting Tests

Q1: Why is surface preparation crucial?

A: 70–80% of coating failures occur due to poor surface prep. Proper cleanliness and roughness ensure strong adhesion.

Q2: What’s the difference between WFT and DFT?

A: WFT is measured right after application; DFT is the final dry thickness after curing.

Q3: How does the holiday test detect defects?

A: It identifies tiny pores or discontinuities using electrical methods before coating goes into service.

Q4: How is corrosion resistance tested?

A: Using salt spray (ASTM B117) or cyclic corrosion (ISO 11997) tests that simulate real-world conditions.

Q5: Which industries use coating tests most?

A: Oil & Gas, Marine, Power, Infrastructure, and Chemical Plants rely heavily on coating inspection for asset integrity.

Conclusion

Coating and painting tests form the core of corrosion protection in modern engineering projects. From cleaning the steel surface to verifying film thickness, adhesion, and long-term weathering, each test ensures the coating system performs flawlessly.

By integrating these tests into every project’s QA/QC procedure, companies can extend asset life, reduce failures, and guarantee compliance with ASTM, ISO, NACE, and SSPC standards.

✨ Remember: A coating is not just applied — it’s verified, tested, and trusted.