Corrosion is much more than just rust forming on metal. It is the gradual breakdown of metals caused by chemical or electrochemical reactions with elements such as moisture, oxygen, acids, salts, or other environmental chemicals. Over time, corrosion weakens the surface and structure of metals, reducing their strength, appearance, and overall functionality.

Left unchecked, corrosion can compromise safety, reliability, and the economic life of equipment and structures. That’s why industries like oil & gas, marine, power, and manufacturing treat corrosion control as a top priority.

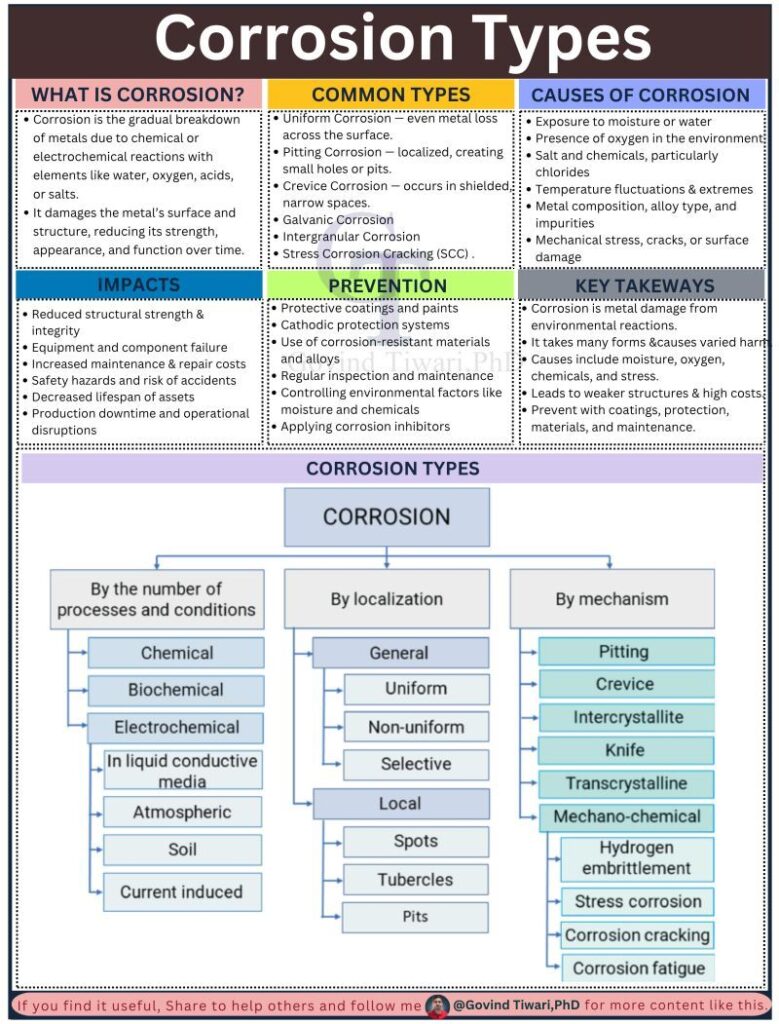

Common Types of Corrosion

Different environments and conditions create different forms of corrosion. The most common include:

- Uniform Corrosion – Even, predictable surface metal loss across a component.

- Pitting Corrosion – Localized attack that produces pits or small holes; extremely dangerous as it causes severe damage with little overall metal loss.

- Crevice Corrosion – Occurs in narrow, shielded spaces (e.g., between flanges, under gaskets).

- Galvanic Corrosion – Arises when dissimilar metals are electrically connected in the presence of an electrolyte.

- Intergranular Corrosion – Attacks along the grain boundaries of alloys.

- Stress Corrosion Cracking (SCC) – Crack growth caused by the combined effect of stress and corrosive environment.

Causes of Corrosion

Corrosion is influenced by environmental and material factors. Some of the most common causes are:

- Exposure to moisture and oxygen – The most basic requirement for corrosion reactions.

- Salt and chemicals – Especially chlorides, which accelerate corrosion in marine and industrial environments.

- Temperature fluctuations & extremes – Accelerate reactions and stress metals.

- Metal composition & impurities – Alloy type and quality impact corrosion resistance.

- Mechanical stress, cracks, and surface damage – Provide initiation points for localized corrosion.

Impacts of Corrosion

The consequences of corrosion can be severe:

- Reduced structural strength and integrity.

- Equipment failure, sometimes catastrophic.

- Increased maintenance and repair costs.

- Safety hazards and risk of accidents.

- Shortened asset lifespan.

- Production downtime and operational disruptions.

Prevention Strategies

The good news is that corrosion can be controlled with a proactive approach. Prevention involves a combination of materials engineering, protective systems, and maintenance practices, guided by international standards.

Common strategies include:

- Protective coatings and paints to isolate metal surfaces.

- Cathodic protection systems (impressed current or sacrificial anodes) as per NACE SP0169 / API 651.

- Use of corrosion-resistant materials and alloys (stainless steels, nickel alloys, composites).

- Regular inspection and monitoring as per API 571 / ISO standards.

- Applying corrosion inhibitors to fluid systems.

- Controlling environmental factors like humidity, salts, and pollutants.

Key International Standards

To ensure consistency, safety, and reliability, industries follow globally recognized corrosion standards:

- API 571 – Damage Mechanisms Affecting Fixed Equipment in the Refining Industry

- API 651 / API 652 – Cathodic Protection & Lining of Aboveground Storage Tanks

- ISO 12944 – Corrosion protection of steel structures by protective paint systems

- ISO 9223–9226 – Classification of environments based on corrosion risk

- NACE MR0175 / ISO 15156 – Materials for H₂S-containing (sour gas) environments

- NACE SP0169 – Control of External Corrosion on Underground/Submerged Metallic Piping

Key Takeaways

- Corrosion is metal damage from environmental reactions.

- It appears in many forms — from uniform surface loss to dangerous localized cracking.

- Causes include moisture, oxygen, salts, stress, and impurities.

- Prevention saves money, prevents accidents, and extends asset life.

- Following NACE, API, and ISO standards ensures compliance and reliability.

Final Words

Corrosion is silent but costly. In industries like oil & gas, marine, infrastructure, and manufacturing, corrosion control is not optional — it’s essential. By adopting the right design practices, material choices, protective systems, and disciplined inspection regimes, organizations can prevent unexpected failures and safeguard both assets and people.

A well-planned, standards-backed corrosion management program ensures long-term reliability, safety, and cost savings.