When it comes to welded structures in high-risk industries such as oil & gas, petrochemicals, offshore engineering, and power generation, understanding how cracks behave under real-world stresses isn’t optional—it’s essential. This is where Crack Tip Opening Displacement (CTOD) testing plays a critical role.

CTOD provides engineers and inspectors with an accurate measure of a material’s fracture toughness and its resistance to brittle failure. Unlike traditional impact toughness tests (such as Charpy), CTOD goes deeper by simulating real-world crack behavior under service conditions, making it indispensable for ensuring safety and reliability.

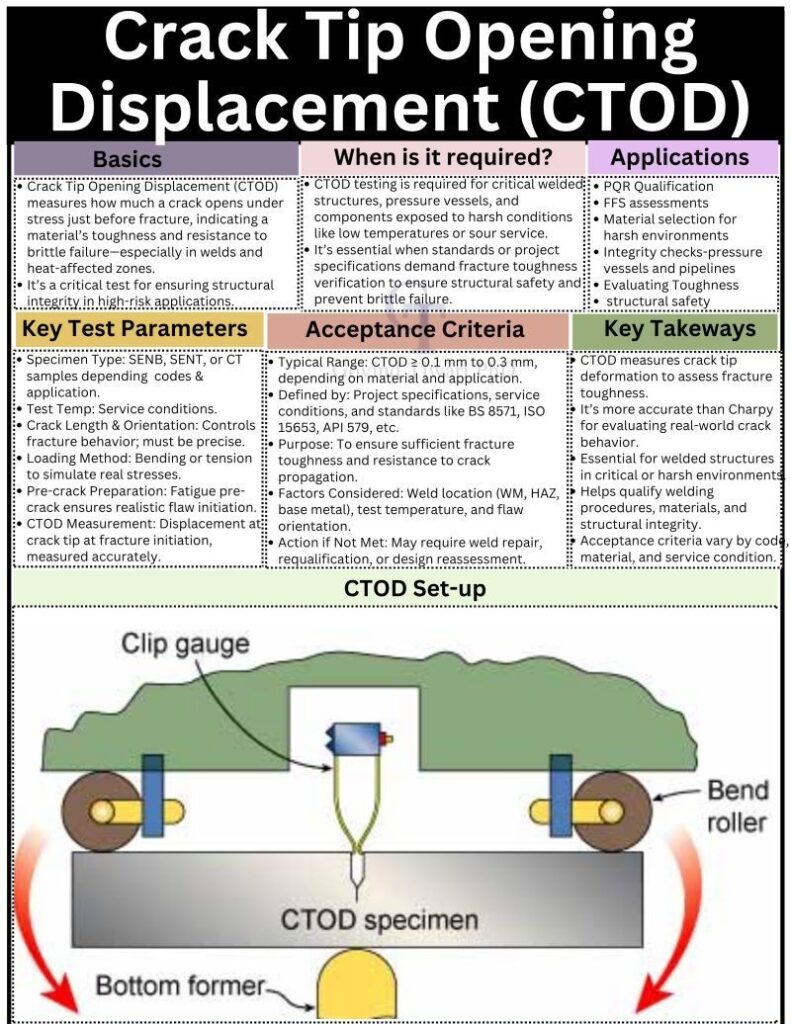

📌 Basics of CTOD

- Definition: CTOD measures the extent to which a crack tip opens under applied stress before fracture occurs.

- Purpose: It directly evaluates a material’s toughness and ability to resist crack propagation.

- Critical Zones: Particularly important for welded joints and heat-affected zones (HAZ) where cracks are more likely to initiate.

- Industry Importance: Ensures structural integrity in pipelines, offshore platforms, ships, bridges, and pressure vessels.

🧪 When is CTOD Required?

CTOD testing is not always mandatory, but it becomes essential in situations where safety and reliability are non-negotiable:

- Critical Welded Joints: Ensures weldments in pressure vessels, storage tanks, and pipelines can withstand service stresses.

- Low Temperature / Sour Service Conditions: Validates fracture toughness in environments prone to embrittlement.

- Project Specifications: Many industry codes and client standards demand CTOD as a prerequisite.

- Risk Mitigation: Prevents catastrophic brittle failure that could lead to leaks, explosions, or structural collapse.

🔩 Applications of CTOD

CTOD testing finds wide applications across industries:

- PQR Qualification: Used during Procedure Qualification Record approval to verify weld procedure robustness.

- Fitness For Service (FFS) Assessments: Evaluates whether a component with flaws can safely remain in operation.

- Material Selection: Helps engineers choose materials for harsh environments (low temp, sour gas, high pressure).

- Integrity Checks: Essential for pressure vessels, pipelines, and offshore platforms.

- Fracture Toughness Evaluation: Provides assurance for structural safety and long-term performance.

⚙️ Key Test Parameters

The accuracy of a CTOD test depends on several parameters:

- Specimen Types: SENB (Single Edge Notched Bend), SENT (Single Edge Notched Tension), or CT (Compact Tension), depending on the application and code.

- Test Temperature: Conducted at service-specific temperatures to replicate real operating conditions.

- Crack Length & Orientation: Precisely controlled to simulate real flaws.

- Loading Method: Bending or tensile loading applied to simulate actual stress conditions.

- Pre-Crack Preparation: Fatigue pre-cracking ensures realistic flaw initiation.

- Measurement: Displacement at the crack tip is measured with a clip gauge for high accuracy.

🧰 CTOD Test Set-Up

A typical CTOD test setup includes:

- Specimen Placement – The CTOD specimen is positioned between bend rollers and a bottom former.

- Clip Gauge – A sensitive measuring device mounted near the crack tip to capture displacement.

- Controlled Loading – The specimen is bent or tensioned under controlled force to simulate service stresses.

This setup ensures real-world simulation of how cracks behave in welded or base materials.

✅ Acceptance Criteria

Acceptance of CTOD results is determined by codes, project specifications, and service requirements:

- Typical Range: CTOD values generally fall between 0.1 mm to 0.3 mm, depending on material and application.

- Standards & Codes: Common references include BS 7910, BS 8571, ISO 15653, and API 579.

- Factors Considered: Weld location (Weld Metal, HAZ, Base Metal), flaw orientation, and service temperature.

- If Criteria Not Met: Options include weld repair, requalification, or structural redesign.

- Objective: To ensure sufficient fracture toughness and resistance against crack propagation.

🎯 Key Takeaways

- CTOD is more precise than Charpy testing when assessing fracture toughness.

- It measures actual crack tip deformation, providing a true reflection of service performance.

- Critical for welded structures in pipelines, offshore rigs, and pressure vessels.

- Helps engineers qualify welding procedures, materials, and structural designs.

- Acceptance criteria vary depending on applicable code, material grade, and service environment.

🧠 Final Thoughts

If Charpy tells you whether a material is tough or brittle, CTOD tells you how it will actually behave under real-world cracks and stresses. For industries where safety is paramount, CTOD is not just a test—it’s a lifeline.

👉 Think beyond Charpy—go fracture-focused with CTOD for a safer, stronger future in welding and fabrication.

🔄 If you found this useful:

💬 Comment with your experience | 🔁 Share with your peers | 🔔 Follow for more insights into welding, NDT, and material science.

#CTOD #FractureToughness #WeldTesting #QAQC #NDT #OilAndGas #WeldingEngineering #PipelineIntegrity #PQR #FFS