Welding is both an art and a science — and one of the most misunderstood technical terms in welding is Duty Cycle. Whether you’re a beginner picking your first welding machine or a professional aiming for optimal efficiency, understanding duty cycle can dramatically improve your welding quality, productivity, and machine lifespan.

In this article, we’ll break down:

✔ What duty cycle means

✔ Why it matters in welding

✔ How it’s calculated

✔ Factors that affect it

✔ Practical examples

✔ Tips to choose the right machine

…and more.

What Is Duty Cycle in Welding?

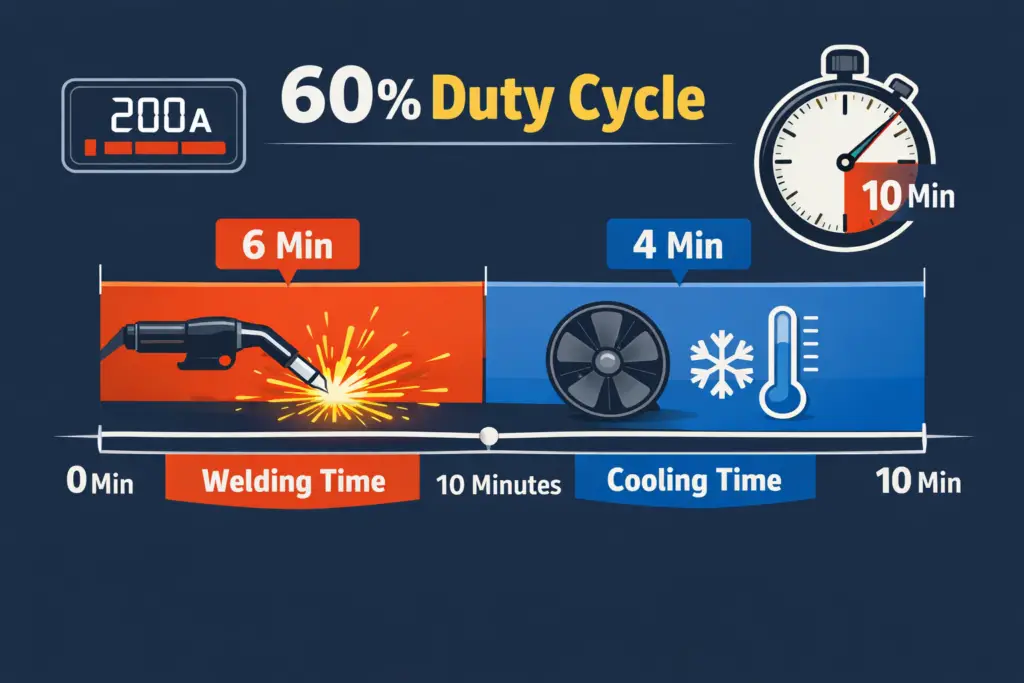

In welding, duty cycle refers to the percentage of time a welding machine can operate continuously within a given time frame — typically 10 minutes — without overheating.

More simply:

Duty cycle tells you how long you can weld before your machine needs to cool down.

For example, if a welder has a 60% duty cycle at a certain amperage:

- It can weld for 6 minutes continuously

- Then must rest for 4 minutes to stay within a 10-minute period.

🔎 This measure ensures components inside the machine — like transformers, capacitors, and IGBT transistors — don’t overheat and fail.

How Duty Cycle Is Expressed

Duty cycle is always presented as:

✔ A percentage

✔ A specific current (amperage) rating

So you might see:

- 60% @ 200 A

- 40% @ 250 A

- 100% @ 150 A

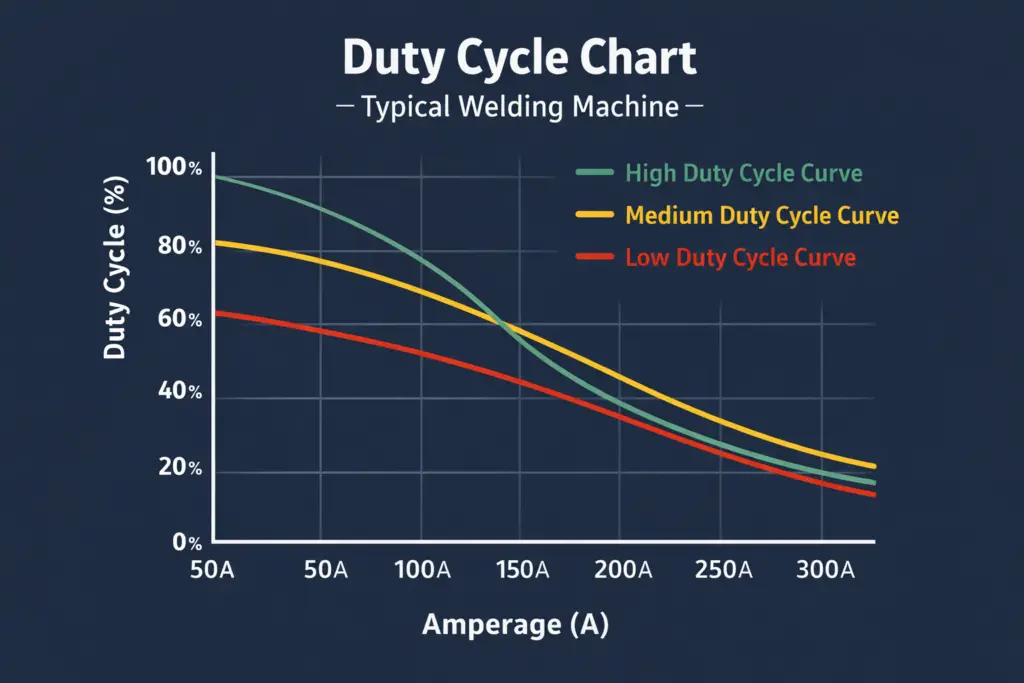

This means the duty cycle depends on the current output: higher amperage usually shortens the duty cycle because the machine heats up faster.

Why Duty Cycle Matters in Welding

Understanding duty cycle is not just technical — it affects real welding tasks:

1. Prevents Overheating and Damage

Exceeding the duty cycle forces the machine to shut down, or worse — damages internal electronics. The thermal overload protection will kick in, but repeated overheating shortens machine life.

2. Matches Machine to Task

For long, continuous welds (e.g., structural steel fabrication), you need a higher duty cycle machine. Hobby projects with intermittent welding can do fine with a lower duty cycle machine.

3. Affects Quality and Efficiency

A machine that overheats frequently causes inconsistent heat input, poor penetration, and warping — all detrimental to weld quality.

How to Calculate Duty Cycle

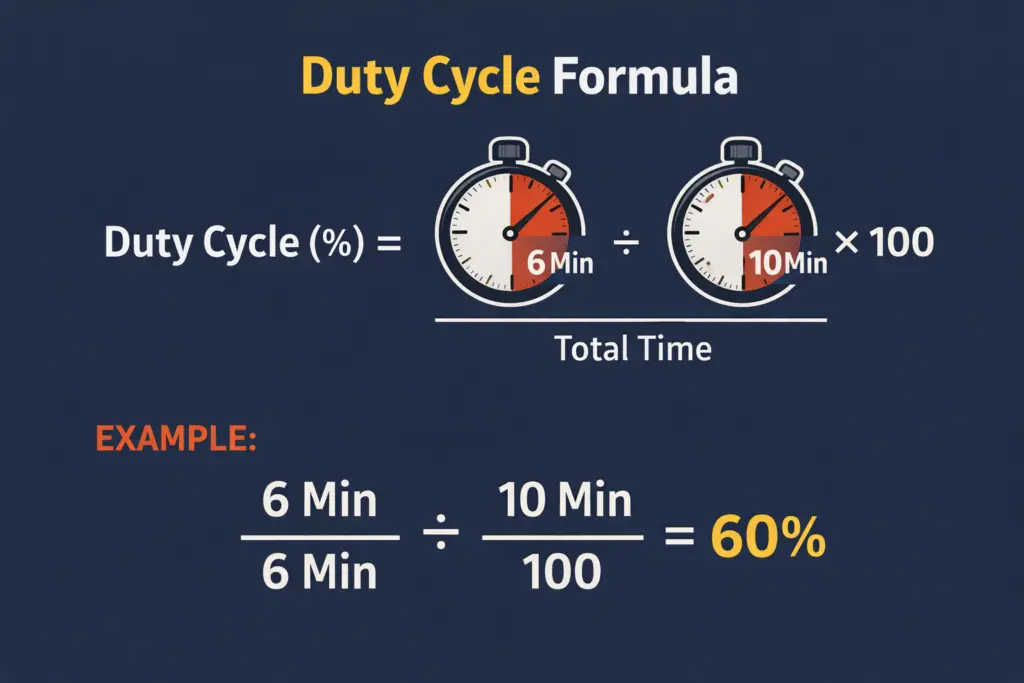

The formula is simple:

Duty Cycle (%) = (Welding Time ÷ Total Time) × 100

So if you weld for 6 minutes and rest for 4 minutes:

(6 ÷ 10) × 100 = 60% duty cycle

Duty cycle Calculation

Factors That Affect Duty Cycle

Duty cycle is not a fixed number. Several variables influence it:

1. Amperage

Higher current = more heat → shorter duty cycle.

2. Ambient Temperature

Hotter environments reduce the effective duty cycle because components heat up faster.

3. Machine Cooling

Better cooling systems (fans, heat sinks) extend duty cycles.

4. Machine Condition

Older or poorly maintained machines generate more internal heat and perform below rated duty cycle.

Duty Cycle Standards

Most duty cycle ratings are tested over a 10-minute period, which is the industry standard. Some manufacturers might use less demanding testing criteria, making their duty cycles seem deceptively high.

Always check whether your machine follows recognized testing standards like EN60974-1.

Duty Cycle and Productivity

A high duty cycle means less downtime and more welding per hour — crucial when you’re working on large welds. Machines with 100% duty cycle can weld continuously without cooling breaks — ideal for industrial jobs.

Real-World Examples

| Duty Cycle | Can Weld | Must Cool |

|---|---|---|

| 20% @ 200 A | 2 min | 8 min |

| 40% @ 250 A | 4 min | 6 min |

| 60% @ 150 A | 6 min | 4 min |

| 100% @ 120 A | 10 min | 0 min |

👉 Notice how heavy tasks at high amperage require more cooling time.

Choosing the Right Welding Machine Based on Duty Cycle

Here’s how to pick:

✅ Small home/farm jobs → lower duty cycle welders

✅ General fabrication → 40–60% duty cycle

✅ Industrial and production welding → 80–100% duty cycle

Don’t just chase the highest duty cycle — match it to your job’s demands.

What Happens If You Exceed Duty Cycle?

Exceeding the duty cycle leads to:

✔ Machine shut-off (thermal overload)

✔ Complete stoppage until cooled

✔ Shortened equipment lifespan

✔ Potential safety issues if ignored

Always allow cooling time, even if you feel the machine seems fine.

Conclusion

Duty cycle is one of the most critical specifications in welding — yet it’s often overlooked. Knowing how to read and use duty cycle values empowers you to:

✔ Choose the right machine

✔ Avoid overheating and damage

✔ Improve welding quality

✔ Plan projects more efficiently

Whether you’re a hobbyist or a professional, understanding duty cycle will make you a better, more informed welder.