In industries like oil & gas, power, petrochemicals, and construction, material quality and traceability are critical. Whether you are a welding inspector, QA/QC engineer, or purchaser, you will frequently come across a Mill Test Certificate (MTC) or Mill Test Report (MTR).

An MTC is a quality assurance document that validates the technical parameters of a material. It confirms compliance with standards and ensures that the supplied product is safe for its intended application. This document provides details such as chemical composition, mechanical properties, manufacturing process, heat treatment, NDE results, and conformance with codes or standards.

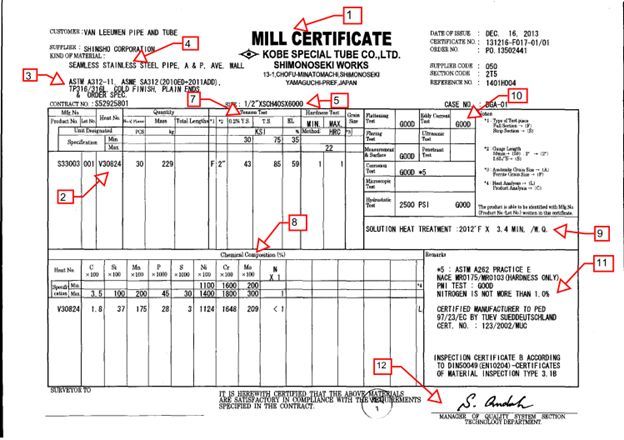

Let’s go step by step and learn how to read a Material Certificate using EN 10204 (Forms 2.1, 2.2, 3.1, and 3.2).

Key Sections of a Mill Certificate

Even though layouts may differ from one manufacturer to another, the basic information is always consistent. Here’s how to interpret the important fields (refer to the sample certificate shown above):

1. Manufacturer

Located at the top, this section mentions the name, logo, or stamp of the producing mill or workshop.

Example: Kobe Special Tube Co., Ltd.

This ensures authenticity and accountability of the supplier.

2. Heat Number (Material Traceability)

The heat number is the most important element on an MTC.

It is the unique traceability number that links the material to its batch production. The same number must appear on the certificate and be hard-stamped on the product itself.

Example: V03242

This allows tracing back the entire production history.

3. Material Grade and Specification

This shows the standard code and grade of the material as per ASTM, ASME, DIN, or EN standards.

Example: ASTM A312 TP316L Seamless Stainless Steel Pipe

The grade defines the alloy, while the specification defines the standard requirements.

4. Delivery Condition

Indicates how the product was manufactured and supplied.

- SMLS = Seamless

- W = Welded

- WX = Welded, radiographed

- WU = Welded, ultrasonically tested

This section also indicates if RT (Radiography Test) or UT (Ultrasonic Test) was performed on weld seams.

5. Material Dimensions

Specifies the size of the product:

- For plates → Thickness × Width × Length

- For pipes → Outside Diameter × Wall Thickness (Schedule)

Example: 1/2″ × SCH 40 × 6000 mm

6. Weight

The weight per piece or per lot.

This is especially important for pipe orders of NPS 4” and above for handling, logistics, and pricing.

7. Mechanical Properties

Lists values of:

- Yield Strength

- Tensile Strength

- Elongation

- Hardness

These values must meet the applicable code requirements (ASME, ASTM, EN, etc.).

Example: Tensile Strength 6000 PSI

8. Chemical Composition

The percentage of each alloying element (C, Mn, Si, Cr, Ni, Mo, etc.) is listed here.

This ensures the material is of the correct grade.

Example: Cr 16–18%, Ni 10–12%, Mo 2–3%

9. Heat Treatment

Provides details of heat treatment cycles applied to the material such as:

- Normalized

- Quenched & Tempered

- Solution Annealed

Example: Solution Heat Treatment: 2012°F × 3.4 min / in.

This ensures the material achieves the required mechanical properties.

10. NDE Testing / Hydrotest

Lists Non-Destructive Examination (NDE) methods or pressure tests carried out:

- Radiography

- Ultrasonic Testing

- Hydrostatic Test

- Impact Test

Example: Hydrotest 2500 PSI

11. Supplementary Requirements

Any additional requirements requested by the client or project specifications are included here, such as:

- Positive Material Identification (PMI)

- NACE MR0175 Compliance

- Intergranular Corrosion Test (IGC)

12. Mill Signature & Stamp

The final section contains the authorized signature and official stamp of the manufacturer.

This confirms the authenticity and validity of the MTC.

Types of Material Certificates (EN 10204)

EN 10204 defines the different inspection certificate types, ranging from simple compliance statements to full independent verification.

- Material Certificate 2.1

- Simple declaration of compliance with order requirements.

- No test results included.

- Material Certificate 2.2

- Includes general test results from the manufacturer.

- Not linked to the specific batch supplied.

- Material Certificate 3.1

- Includes actual test results carried out on the supplied batch.

- Signed by a representative independent from the production department.

- Most commonly used in industries like Oil & Gas and Power.

- Material Certificate 3.2

- Highest level of assurance.

- Certificate validated by both the manufacturer and an independent third-party inspector (TPI) or client representative.

- Required in critical applications such as offshore, nuclear, or high-risk pressure systems.

Why Understanding MTCs Matters?

- Ensures material traceability from mill to site.

- Confirms compliance with design codes and standards.

- Prevents material mix-ups and reduces safety risks.

- Provides confidence during audits and inspections.

In conclusion, reading a material certificate (MTC/MTR) is an essential skill for engineers, inspectors, and procurement professionals. By carefully checking each field — from the manufacturer’s stamp to the chemical analysis and mechanical test results — you can ensure that the materials delivered are safe, compliant, and reliable.