Welding is the backbone of modern fabrication and construction. Whether it is pressure vessels, pipelines, bridges, or structural components, weld quality directly determines safety and reliability. Among all welding defects, Lack of Fusion (LOF) — also known as Incomplete Fusion — is one of the most critical because it compromises both strength and integrity of welded joints.

What is Lack of Fusion?

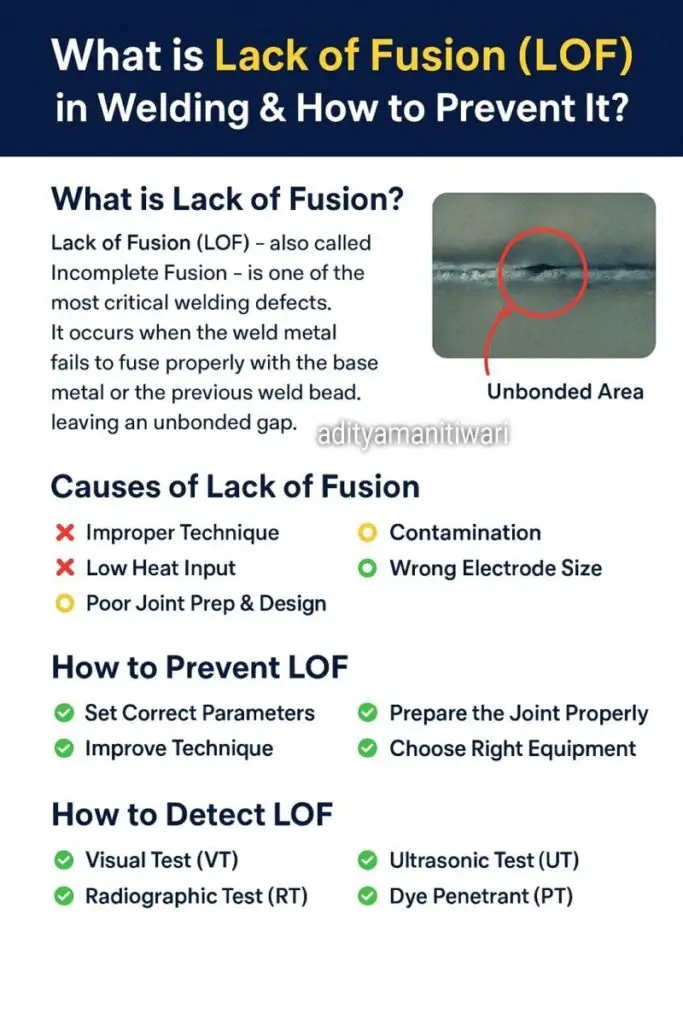

Lack of Fusion occurs when the weld metal fails to fuse properly with the base metal or the previous weld bead, leaving an unbonded gap. Unlike porosity or undercut, LOF is far more dangerous because it behaves like a sharp crack or notch in the weld, creating a stress concentration zone that can trigger catastrophic failure under loading conditions.

Where Can LOF Occur?

- Sidewall Fusion: The arc fails to melt or fuse with the joint edge.

- Interpass Fusion: Occurs between successive weld passes or layers.

- Root Fusion: Found at the root of the weld joint where penetration is insufficient.

These defects are often hidden inside the weld and not always visible to the naked eye, which makes detection and prevention even more important.

Why is Lack of Fusion Dangerous?

- Reduces Strength: Since parts of the weld remain unbonded, the joint cannot carry designed loads.

- Acts Like a Crack: The sharp edges of LOF behave like pre-existing cracks, easily propagating under stress.

- Leads to Failure: In pressure vessels, pipelines, and critical structures, LOF can lead to leakage, rupture, or collapse.

In industries such as oil & gas, power generation, shipbuilding, and aerospace, LOF is considered an unacceptable defect.

Causes of Lack of Fusion

LOF does not occur randomly — it usually points to poor technique, wrong parameters, or insufficient joint preparation. Below are the major causes:

1. Improper Technique

- Steep electrode angle → arc bypasses joint edges.

- Fast travel speed → weld pool rides over cold base metal.

- Long arc length → heat spreads instead of penetrating.

2. Low Heat Input

- Low amperage → insufficient energy to melt base metal.

- High voltage → wide, soft arc with poor penetration.

3. Poor Joint Preparation & Design

- Narrow groove angle → arc cannot access the root.

- Excessive root face or poor fit-up → restricts penetration.

4. Contamination

- Rust, oil, grease, mill scale, and paint prevent bonding.

- Aluminum oxides (Al₂O₃) form a refractory barrier that resists fusion.

5. Wrong Electrode Size

- Oversized electrodes restrict root access.

- Incorrect filler choice can lead to incompatibility.

How to Prevent Lack of Fusion

Preventing LOF requires a combination of correct welding parameters, good practices, and discipline in joint preparation.

Set Correct Parameters

- Use proper amperage for full penetration.

- Maintain a short arc length.

- Avoid high voltage that softens the arc.

Improve Technique

- Maintain proper travel angle and work angle.

- Pause or weave slightly on sidewalls for penetration.

- Control travel speed — not too fast, not too slow.

Prepare the Joint Properly

- Clean thoroughly by grinding or brushing rust, paint, and oil.

- Ensure correct groove angle and root gap as per WPS (Welding Procedure Specification).

- Remove oxides in aluminum welding with stainless steel brushes.

Choose Right Equipment

- Select electrode size suitable for root access.

- Adjust arc force/dig settings for stable penetration.

- Use proper shielding gas and filler metal for the application.

How to Detect Lack of Fusion

Since LOF may not always be visible on the surface, inspection techniques are critical.

- Visual Testing (VT): Can reveal visible linear defects, especially at toes.

- Radiographic Testing (RT): Shows dark linear defects on X-ray films.

- Ultrasonic Testing (UT): Most reliable for detecting planar defects inside welds.

- Dye Penetrant Testing (PT): Effective for surface-breaking LOF.

Practical Welding Tips to Avoid LOF

- Low amps + fast travel speed = LOF risk → slow down and increase heat.

- Always grind or clean surfaces before welding.

- Maintain proper electrode angle and arc length.

- Follow WPS strictly for critical projects.

Conclusion

Lack of Fusion (LOF) is not just a cosmetic defect — it is a structural hazard. For welders, engineers, and inspectors, understanding the causes and implementing preventive measures is the only way to ensure reliable welds. High-quality welding is not only about depositing metal but ensuring complete metallurgical bonding between weld and base metal.

By maintaining correct welding techniques, using proper parameters, preparing joints well, and carrying out reliable testing, we can minimize LOF and guarantee welds that stand the test of time.