Introduction to Long Range Ultrasonic Testing (LRUT)

Long Range Ultrasonic Testing (LRUT), also known as Guided Wave Ultrasonic Testing (GWUT), is an advanced non-destructive testing (NDT) technique used to inspect long sections of pipelines, rails, and similar structures from a single test location. Unlike conventional ultrasonic testing, which inspects only a small local area, LRUT can examine up to 100 meters or more in both directions.

This makes LRUT highly valuable for industries where access is limited, insulation removal is costly, or shutdown time must be minimized.

What is Long Range Ultrasonic Testing?

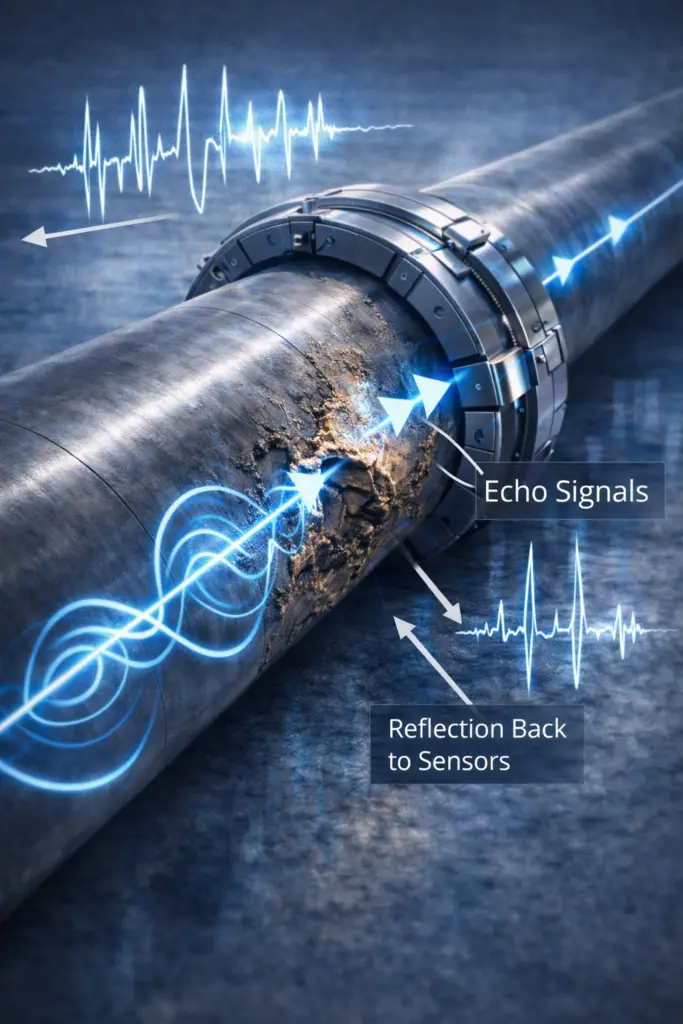

LRUT uses low-frequency ultrasonic guided waves that propagate along the length of a structure rather than straight through its thickness. These waves interact with changes in geometry such as corrosion, metal loss, welds, or defects and reflect back to the sensors.

By analysing the reflected signals (echoes), inspectors can identify the location and severity of defects without scanning the entire surface manually.

How Does Long Range Ultrasonic Testing Work?

The LRUT inspection process follows these steps:

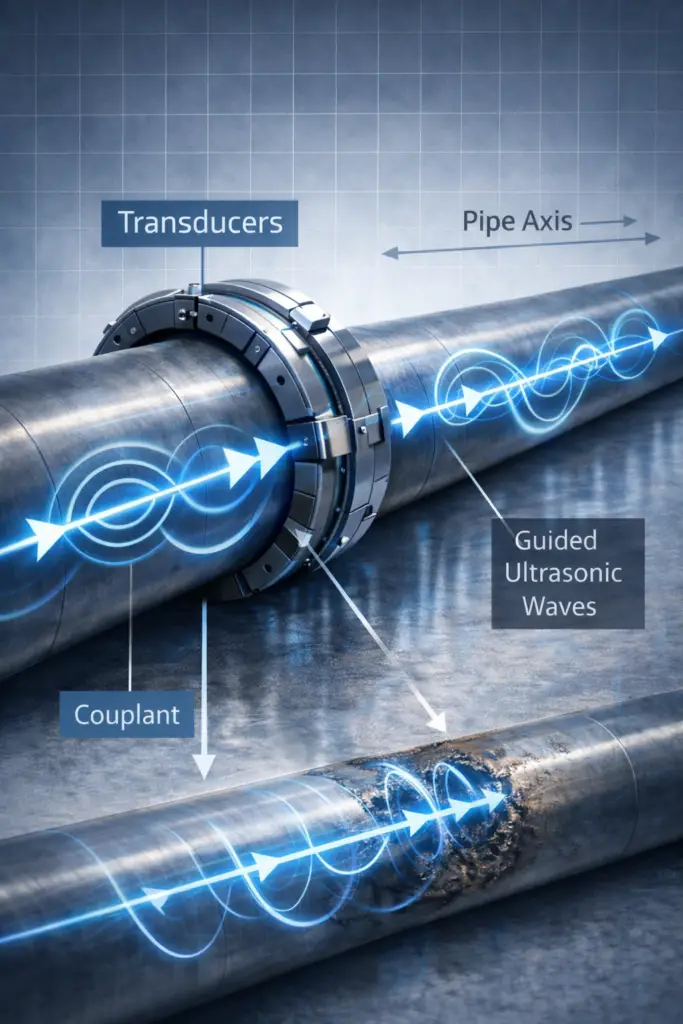

- A ring of ultrasonic transducers is clamped around the pipe circumference

- Transducers generate low-frequency guided waves (typically 15–85 kHz)

- Waves travel along the pipe in both directions

- When waves encounter corrosion, welds, or defects, part of the energy reflects back

- Reflected signals are captured and analysed using specialized software

This allows technicians to screen large pipeline sections quickly and efficiently.

LRUT vs Conventional Ultrasonic Testing

| Feature | Conventional UT | LRUT |

|---|---|---|

| Inspection range | Few centimeters | 100+ meters |

| Access required | Full surface access | Single test point |

| Insulation removal | Required | Minimal |

| Inspection speed | Slow | Fast |

| Application | Local defect sizing | Long-range screening |

LRUT is not a replacement for conventional UT but acts as a screening tool to identify areas that need further detailed inspection.

Defect Detection in LRUT

LRUT is particularly effective in detecting:

- Corrosion under insulation (CUI)

- General wall thinning

- Localized metal loss

- Weld-related anomalies

- Erosion damage

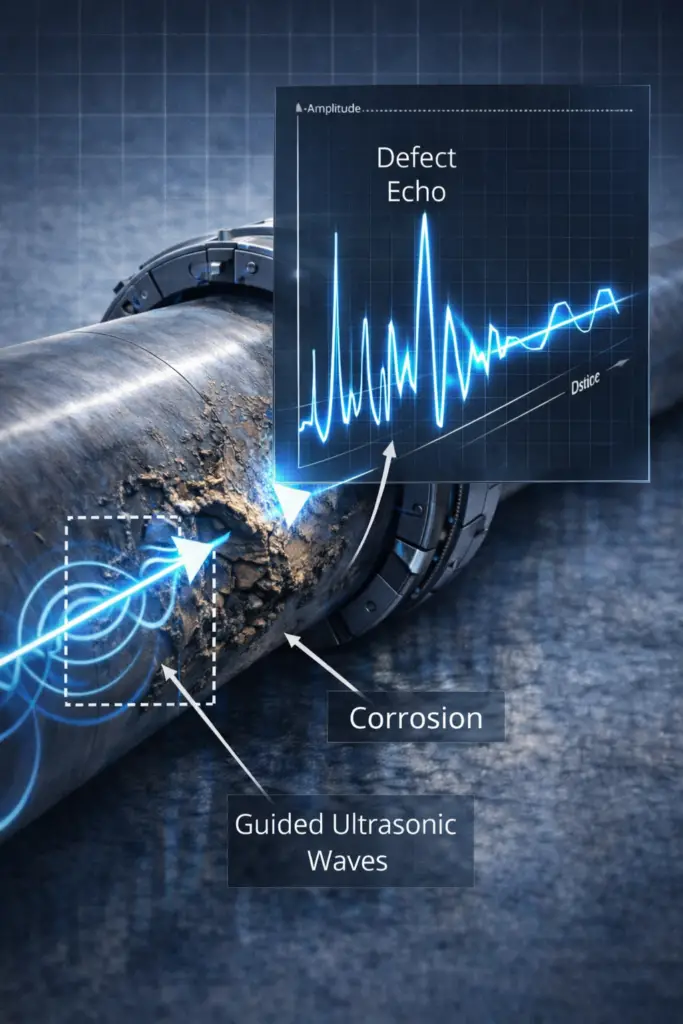

The technique detects changes in cross-sectional area, not exact defect shape, which is why it is best suited for screening rather than precise sizing.

Interpretation of LRUT Signals

LRUT data is typically displayed as A-scan waveforms, where:

- X-axis represents distance along the pipe

- Y-axis represents signal amplitude

- Peaks indicate reflections from features or defects

Experienced analysts distinguish between known features (welds, flanges) and actual defects based on signal pattern and location.

Advantages of Long Range Ultrasonic Testing

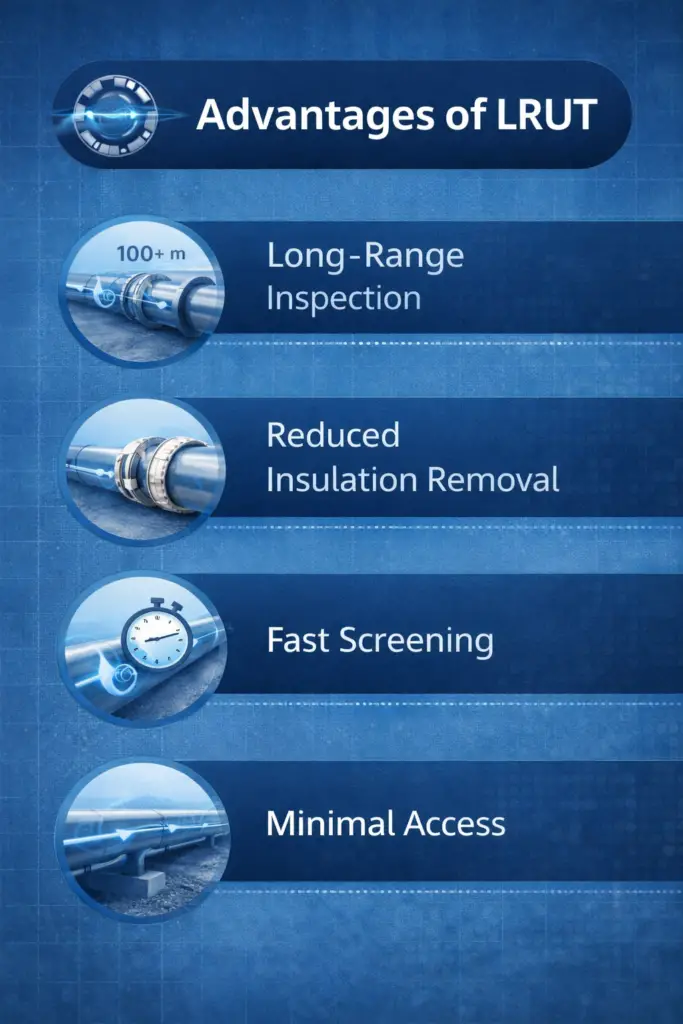

LRUT offers several major advantages:

- ✅ Long-range inspection from one location

- ✅ Minimal insulation removal

- ✅ Reduced scaffolding and access cost

- ✅ Fast screening of large assets

- ✅ Non-destructive and safe

These benefits make LRUT ideal for condition monitoring and preventive maintenance programs.

Limitations of LRUT

Despite its strengths, LRUT has limitations:

- Cannot accurately size defects

- Complex geometries cause signal reflections

- Requires skilled interpretation

- Less effective near bends and branches

Therefore, LRUT results are often followed by conventional UT or PAUT for detailed inspection.

Applications of Long Range Ultrasonic Testing

LRUT is widely used in:

- Oil & gas pipelines

- Refineries and petrochemical plants

- Power plants

- Railway track inspection

- Industrial piping networks

It is especially valuable where pipelines are buried, elevated, insulated, or difficult to access.

Conclusion

Long Range Ultrasonic Testing is a powerful NDT screening technique that enables fast, cost-effective inspection of long pipelines and structures. While it does not replace conventional ultrasonic methods, it significantly reduces inspection time and cost by identifying high-risk areas early.

For industries focused on asset integrity, safety, and pance, LRUT is an indispensable inspection tool.