Though often used interchangeably in everyday language, pipes and tubes serve very different roles in the world of engineering, construction, manufacturing, and industrial systems. Misunderstanding these differences can lead to incorrect material selection, poor performance, inspection failures, or increased costs. That’s why understanding the key distinctions between pipe and tube isn’t just academic—it’s essential.

Let’s dive into the detailed comparison of pipe vs tube, highlighting the dimensional basis, application areas, standards, and why choosing the right one matters.

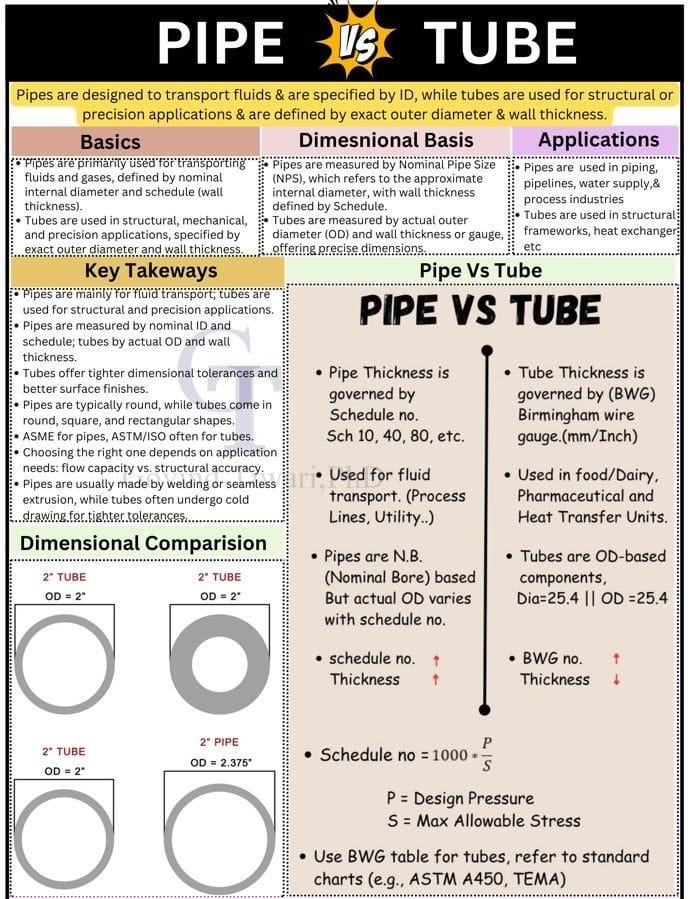

🎯 Dimensional Basis

➤ Pipes:

- Measured by Nominal Pipe Size (NPS), which refers to the approximate internal diameter (ID).

- Wall thickness is specified by a Schedule number (like Sch 10, 40, 80, etc.).

- As the Schedule number increases, wall thickness increases, but the outer diameter (OD) remains relatively constant.

- Example: A 2” pipe may have an OD of 2.375”, regardless of schedule, but its ID will vary depending on wall thickness.

➤ Tubes:

- Defined by the actual outer diameter (OD) and wall thickness or gauge (BWG – Birmingham Wire Gauge).

- OD remains fixed, and wall thickness determines the strength and flow capacity.

- Tighter manufacturing tolerances for dimensional precision.

Visual Insight (from infographic):

- A 2” tube always has an OD of 2”.

- A 2” pipe has an OD of 2.375”, but its ID will vary based on the schedule.

🚀 Applications

➤ Pipe Applications:

- Primarily used for fluid and gas transportation.

- Common in:

- Oil & Gas

- Water pipelines

- HVAC systems

- Chemical and Process industries

➤ Tube Applications:

- Used in structural, mechanical, and precision applications.

- Found in:

- Automotive and Aerospace components

- Heat Exchangers

- Instrumentation

- Food, Dairy & Pharmaceutical equipment

🔍 Key Differences

| Feature | Pipe | Tube |

|---|---|---|

| Dimensional Basis | Nominal ID (NPS) & Schedule | Exact OD & Wall Thickness |

| Use | Fluid transport | Structural & precision |

| Tolerances | Less precise | Tighter |

| Shapes | Mostly round | Round, square, rectangular |

| Surface Finish | Standard | Superior |

| Cost | Less expensive | Higher due to precision |

⚠️ Challenges in Selection

Choosing the wrong product can lead to:

- Flow issues due to incorrect wall thickness in pipes.

- Over-specification and cost escalation if tubes are used where pipes would suffice.

- Inspection failures when dimensional precision is expected but not achieved.

- Design limitations due to unavailability of specific sizes or materials.

📚 Industry Standards

Understanding the right codes and standards is crucial:

➤ Pipes:

- ASME B36.10 / B36.19 – Dimensions for carbon/stainless pipes

- API 5L – Line pipe specifications

- ASTM A106 / A53 – Seamless and welded pipes

➤ Tubes:

- ASTM A213 – Heat exchanger tubes

- ASTM A269 – Stainless steel tubing

- ASTM A500 – Structural tubing

- ISO 657 – International tube dimensions

🔑 Key Takeaways

- ✅ Choose pipes when transporting fluids or gases under pressure—focus on flow rate and pressure ratings.

- ✅ Choose tubes for dimensional accuracy, strength, and aesthetic or structural purposes.

- ✅ Always refer to industry codes to ensure compliance.

- ✅ Understanding the fundamental difference improves design efficiency, cost control, and system reliability.

📏 Dimensional Formulas

- Pipe Thickness: Governed by Schedule No. Schedule No.=1000×PS\text{Schedule No.} = \frac{1000 \times P}{S}Schedule No.=S1000×P where,

P=Design PressureP = \text{Design Pressure}P=Design Pressure,

S=Maximum Allowable StressS = \text{Maximum Allowable Stress}S=Maximum Allowable Stress - Tube Thickness: Based on BWG (Birmingham Wire Gauge); refer to charts like ASTM A450 or TEMA.

💬 Real-World Perspective

Have you ever encountered confusion between pipe and tube on a project? Maybe a structural tube was used where a fluid-handling pipe was required—or vice versa?

Such mismatches can lead to:

- Unexpected system failures

- Code compliance issues

- Delayed inspections or rework

Let’s discuss your experiences and best practices in the comments!

📌 Summary Table – Pipe vs Tube

| Feature | Pipe | Tube |

|---|---|---|

| Measured By | Nominal Bore (NPS) | Actual Outer Diameter |

| Thickness | Schedule (e.g., 40, 80) | Gauge (e.g., BWG 16) |

| Applications | Fluids & gases | Structures, Heat exchangers |

| Tolerance | Lower | Higher |

| Surface Finish | Standard | Superior |

| Standards | ASME, API, ASTM | ASTM, ISO |

| Cost | Lower | Higher |

Pro Tip: When in doubt, check the application—if it flows, it’s pipe; if it supports, it’s tube!