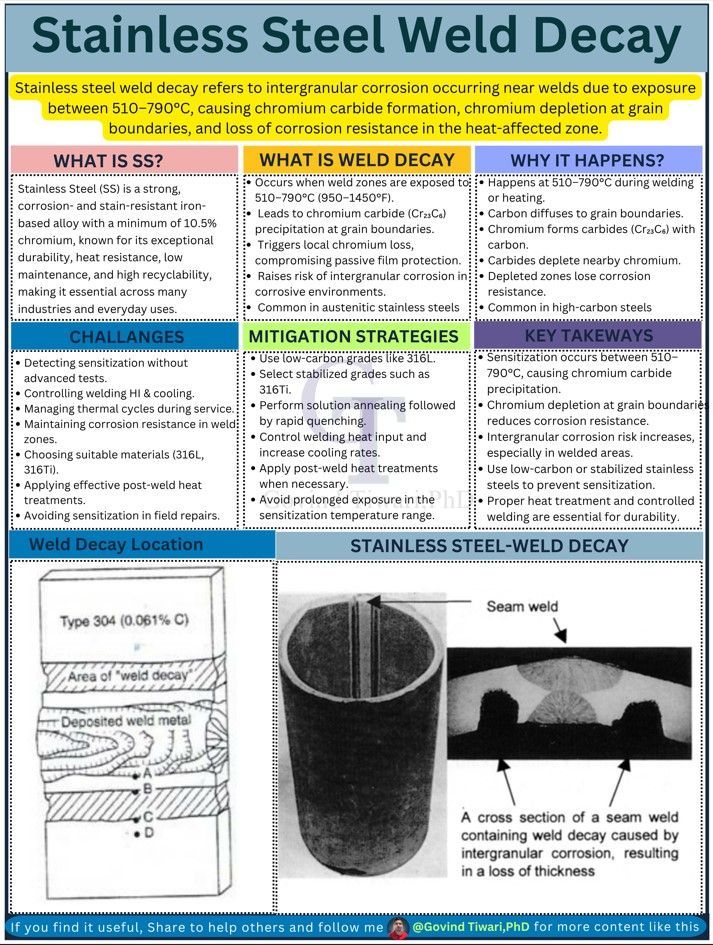

Welded stainless steel components are prized in industries for their exceptional strength, heat resistance, and corrosion resistance. From chemical plants and refineries to food processing and marine applications, stainless steels are trusted for their durability. However, despite their superior performance, stainless steels are not immune to certain metallurgical challenges. One of the most critical of these is Weld Decay – a hidden threat that can compromise the longevity of welded structures if not properly addressed.

🎯 What is Weld Decay?

Weld Decay is a form of intergranular corrosion that typically develops in the heat-affected zone (HAZ) of stainless steel during or after welding. When stainless steel is exposed to temperatures between 510–790°C (950–1450°F) for extended periods, chromium carbide (Cr₂₃C₆) precipitates at grain boundaries.

This phenomenon has two critical consequences:

- Chromium Depletion: Chromium atoms are pulled from the surrounding matrix to form carbides, lowering chromium concentration below the critical 10.5% level at grain boundaries.

- Loss of Passivity: Without sufficient chromium, the protective oxide film cannot reform, leaving the depleted areas vulnerable to corrosive attack.

The result is localized intergranular corrosion, which can propagate undetected and eventually lead to catastrophic structural failures.

⚠️ Why Does Weld Decay Happen?

Weld decay is primarily a result of thermal cycles during welding or heating. The mechanism involves:

- Exposure to sensitization range (510–790°C): This is the danger zone for chromium carbide formation.

- Precipitation of chromium carbides: At grain boundaries, carbides lock up chromium.

- Chromium-depleted regions: Surrounding areas lose their corrosion resistance.

- Environmental exposure: In corrosive media (acids, chlorides, seawater), these weakened areas corrode preferentially.

It is especially prevalent in austenitic stainless steels such as Type 304 or 316, which are commonly used but sensitive to improper welding practices.

🧩 Challenges with Weld Decay

- Detecting sensitization often requires advanced tests like ASTM A262 practices (e.g., oxalic acid etch).

- Controlling heat input and cooling during welding can be difficult in field conditions.

- High carbon grades (e.g., 304, 316) are more prone compared to low-carbon variants (304L, 316L).

- In cyclic thermal service, sensitization risk increases further.

- Repair welds may re-expose material to sensitization range.

🛠️ How to Prevent Weld Decay

Fortunately, weld decay can be prevented or minimized with proper metallurgy and welding discipline. Common strategies include:

- Material Selection:

- Use low-carbon grades (e.g., 304L, 316L) that reduce carbide formation.

- Select stabilized grades (e.g., 316Ti, 321) containing titanium or niobium, which preferentially form carbides instead of chromium.

- Welding Practices:

- Control heat input and interpass temperature.

- Ensure faster cooling rates to minimize carbide precipitation.

- Heat Treatments:

- Apply solution annealing followed by rapid quenching to dissolve carbides and restore corrosion resistance.

- Use post-weld heat treatments (PWHT) only when necessary and suitable.

- Design Considerations:

- Avoid prolonged exposure in the sensitization temperature range.

- Minimize the number of repair welds on critical components.

✅ Key Takeaways

- Weld Decay = Intergranular corrosion in the heat-affected zone of stainless steels.

- It occurs due to chromium carbide precipitation at 510–790°C.

- Chromium depletion at grain boundaries destroys local corrosion resistance.

- Preventive measures include low-carbon/stabilized grades, controlled welding, and solution annealing.

- Weld decay is insidious — it may not show immediate symptoms but can cause severe failures in service.

🔬 Why Understanding Weld Decay Matters

Industries such as petrochemical, nuclear, and marine rely on stainless steels for safety and reliability. A minor welding oversight can initiate weld decay, leading to intergranular attack, leaks, or even structural collapse. Engineers, fabricators, and inspectors must understand this phenomenon to ensure durability, safety, and cost efficiency.

In short, weld decay is not just a metallurgical term — it is a practical challenge that demands attention at every stage of design, fabrication, and inspection.

👉 By mastering weld decay prevention, industries can truly harness the full potential of stainless steels without compromising on performance or safety.