In the world of welding, precision and quality are everything. A single defect in a weld joint can compromise strength, durability, and even safety. One of the most common and often misunderstood welding defects is undercut.

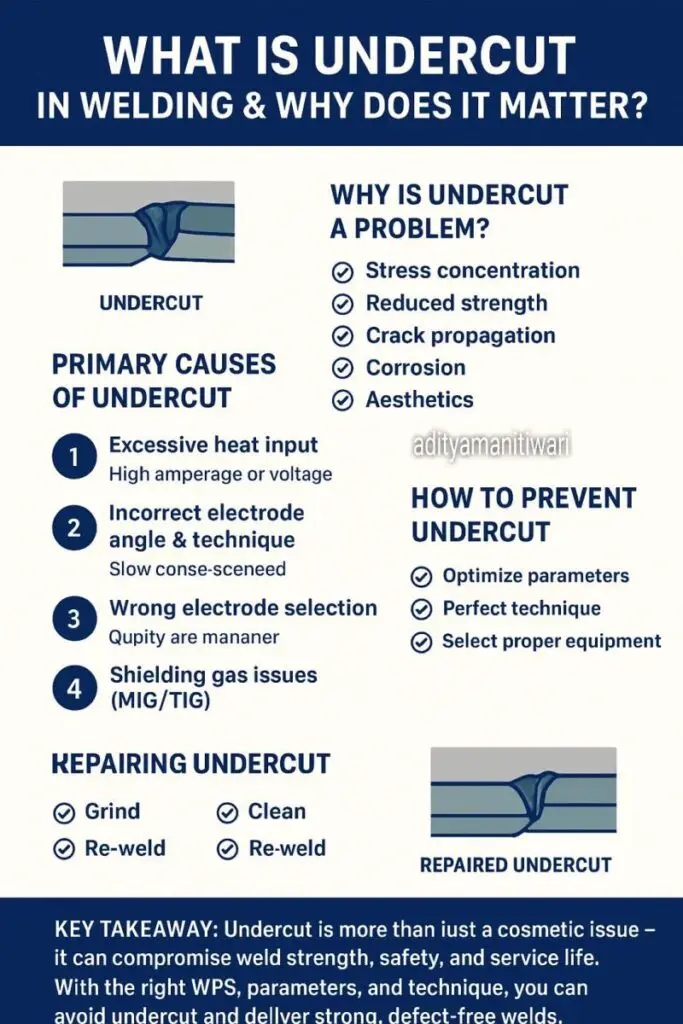

Undercut is a groove or depression that forms along the toe of the weld bead in the base metal and remains unfilled by weld metal. At first glance, it may seem like a small surface imperfection, but in reality, it is a critical flaw that can reduce the effectiveness and life of a weld.

Why is Undercut a Problem?

Undercut is not just a cosmetic issue. It creates weak spots and can lead to premature failure of the welded structure. Here’s why it matters:

- Stress Concentration: The groove acts like a notch, concentrating stress and serving as a starting point for cracks.

- Reduced Strength: Because of the thinner cross-section at the weld toe, the overall load-bearing capacity of the joint decreases.

- Crack Propagation: Even a small undercut can become a path for cracks to spread under cyclic or impact loading.

- Corrosion: The depression traps moisture, dirt, and chemicals, accelerating rust and pitting corrosion, especially in outdoor and marine applications.

- Aesthetics: Even if strength is not compromised, undercut signals poor workmanship, which is unacceptable in industries like aerospace, oil & gas, and pressure vessels.

⚠ In many fabrication codes and standards, a certain amount of undercut is permissible (typically up to 0.5 mm or as per ASME/AWS/DIN standards). However, in critical applications such as pipelines, boilers, and structural bridges, it is usually a rejectable defect.

Primary Causes of Undercut

Understanding what leads to undercut is key to preventing it. Some of the most common causes include:

1️⃣ Excessive Heat Input

- High amperage or voltage burns away the base metal edges.

- Long arc length increases heat at the edges.

- Slow travel speed allows excessive melting, creating a groove.

2️⃣ Incorrect Electrode Angle & Technique

- Too steep of a drag or push angle can gouge the edges.

- Incorrect work angle in fillet and groove welds.

- Pausing at the weld edges during weaving can deepen undercut.

3️⃣ Wrong Electrode Selection

- Oversized electrodes deposit excessive molten metal, washing away base edges.

- Certain electrode types (like high-cellulose rods) are more prone to undercut if not handled properly.

4️⃣ Shielding Gas Issues (MIG/TIG)

- Incorrect gas mixture leads to unstable arcs.

- Low or inconsistent gas flow results in poor shielding and weld pool instability.

How to Prevent Undercut

The best way to deal with undercut is prevention. Welders and inspectors must focus on process control:

✔ Optimize Parameters:

- Reduce heat input by lowering amperage/voltage.

- Maintain correct arc length.

- Adjust travel speed to balance penetration and bead shape.

✔ Perfect Technique:

- Use the correct electrode angle (usually 5–15°).

- Avoid pausing at weld edges during weaving.

- Focus on fully fusing toes of the weld pool without excessive heat.

✔ Select Proper Equipment:

- Choose the right electrode size and type.

- Use proper filler material matching the base metal.

- Ensure correct shielding gas type and flow rate in MIG/TIG welding.

Repairing Undercut

If undercut is detected during inspection, it should be repaired immediately before putting the component into service. The typical repair process includes:

- Grind: Remove the undercut groove to eliminate stress concentration points.

- Clean: Ensure the surface is free of oil, rust, and slag.

- Re-weld: Deposit new weld metal with optimized settings and proper technique.

A repaired undercut, if done correctly, restores the strength and reliability of the joint.

Key Takeaway

Undercut in welding may appear to be a minor surface imperfection, but it has serious consequences. It compromises weld strength, safety, corrosion resistance, and service life.

With the right Welding Procedure Specification (WPS), correct parameters, and skilled technique, undercut can be avoided altogether. Remember – welding isn’t just about joining metals, it’s about ensuring safety, reliability, and quality.

💬 Have you faced undercut in your welding projects? How do you prevent it? Share your experience in the comments below!