In the world of welding, quality is never an accident. It is the result of controlled processes, adherence to standards, and meticulous handling of consumables. One of the most overlooked yet critical practices in welding is the baking of electrodes. Whether in fabrication shops or large-scale construction sites, electrode baking ensures the elimination of moisture from flux-coated electrodes, thereby preventing weld defects and ensuring structural reliability.

What Is Electrode Baking and Why Is It Important?

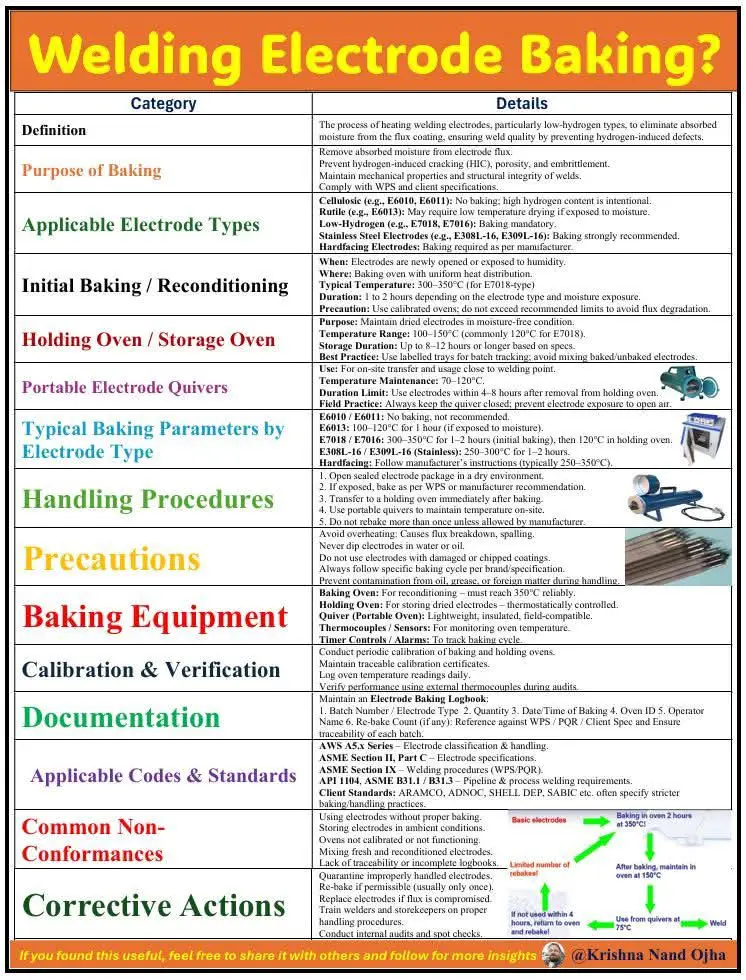

Electrode baking refers to the process of heating welding electrodes, especially low-hydrogen types, to remove any absorbed moisture from the flux coating. Flux coatings are hygroscopic in nature and readily absorb atmospheric humidity when exposed. If electrodes are used without baking, the absorbed moisture can release hydrogen during welding, which becomes trapped in the weld metal. This leads to serious issues such as:

- Hydrogen-Induced Cracking (HIC) or cold cracking

- Porosity and blowholes in welds

- Embrittlement and reduced toughness

- Delayed cracking, which may occur hours or days after welding

Therefore, electrode baking is not just a procedural requirement but a quality assurance step that directly affects the integrity and service life of welded structures.

The 3-Stage Baking Process You Must Follow

1. Initial Baking (Reconditioning)

- Required when electrodes are removed from sealed containers or exposed to humid environments

- Typically carried out at 300–350°C for 1–2 hours depending on the electrode type and manufacturer recommendation

- This step removes deeply absorbed moisture and restores electrodes to their optimum condition

- Essential for low-hydrogen electrodes like E7018, E7016, and stainless steel electrodes

2. Holding Oven Storage

- Once electrodes are baked, they should not be exposed to ambient conditions again

- They must be transferred to holding ovens maintained at 100–150°C

- This prevents reabsorption of atmospheric moisture before usage

- Electrodes can generally be stored in these ovens for up to 12 hours, though client specifications may impose stricter requirements

3. Portable Quivers for Field Use

- During actual welding, electrodes should be carried to the worksite in portable quivers maintained at 70–120°C

- Electrodes must be used within 4–8 hours once removed from the holding oven

- Quivers should remain closed when not in use to minimize exposure to moisture

Which Electrodes Need Baking?

- Mandatory Baking:

Low-hydrogen electrodes (E7018, E7016), Stainless steel electrodes (E308L, E309L), and hardfacing electrodes as per manufacturer recommendation - Recommended if Exposed:

Rutile electrodes (E6013) – may only need low-temperature drying if exposed - Not Required:

Cellulosic electrodes (E6010, E6011) – high hydrogen content is intentional for arc characteristics and penetration

Standards and Codes to Follow

The importance of electrode baking is reflected in various international standards and codes:

- AWS A5 Series – Covers electrode classification, storage, and handling requirements

- ASME Section II, Part C – Specifies material requirements

- ASME Section IX – Governs welder and procedure qualifications

- API 1104, ASME B31.1, B31.3 – Applicable to pipeline and process welding

- Client Specifications – Major oil & gas companies (ARAMCO, ADNOC, Shell, SABIC) often demand stricter control measures, including detailed logbooks and calibrated ovens

Key Best Practices for Electrode Baking

- Always use calibrated ovens and record temperatures daily

- Maintain a baking and usage logbook with batch number, oven ID, operator name, and baking details

- Never rebake electrodes more than once unless permitted by the manufacturer

- Segregate baked and unbaked electrodes using labeled trays

- Use thermocouples and alarms for monitoring oven performance

- Conduct regular calibration and audits to ensure compliance

Common Issues in the Field

Despite clear guidelines, several non-conformances are frequently observed:

- Ovens operating at incorrect temperatures due to faulty thermostats

- Electrodes used directly from open packets without baking

- Improper record-keeping or absence of baking logbooks

- Mixing of different electrode batches leading to traceability issues

- Repeated rebaking which deteriorates flux properties

- Portable quivers not heated or left open at worksites

These lapses can compromise weld quality, lead to rework, and cause costly project delays.

Corrective Actions for Non-Conformance

When deviations occur, immediate corrective actions are necessary:

- Rebake electrodes as per manufacturer guidelines (only if permitted)

- Reject and replace electrodes with damaged flux coatings or multiple baking cycles

- Improve documentation by maintaining logbooks and calibration records

- Train welding personnel on handling, storage, and baking practices

- Audit ovens and equipment periodically to ensure compliance with codes and client requirements

Conclusion

Welding electrode baking is more than a procedural step—it is a quality safeguard that directly impacts weld performance and structural safety. In industries such as oil and gas, power, shipbuilding, and heavy fabrication, strict control over electrode baking can mean the difference between a reliable weld and a catastrophic failure. By adhering to codes, using calibrated equipment, maintaining proper documentation, and instilling best practices, organizations can ensure weld integrity and meet the highest standards of quality and safety.