Gas Metal Arc Welding (GMAW), often referred to as MIG/MAG welding, is one of the most versatile and widely applied welding processes in modern industries. Known for its ease of automation, high deposition rates, and adaptability across materials, it has become a cornerstone in fabrication, automotive, pipeline, and construction projects.

One of the most critical factors that determine the success of a GMAW process is the mode of metal transfer. The way molten metal transfers from the wire electrode to the weld pool has a direct impact on penetration depth, weld bead quality, heat input, spatter levels, and positional welding capability.

In this article, we will explore the different GMAW metal transfer modes, their benefits, limitations, and applications, while also looking at modern developments that make GMAW even more efficient.

⚡ GMAW Basics

The GMAW process uses a continuously fed consumable wire electrode shielded by an external gas to protect the molten weld pool from atmospheric contamination. Depending on the type of shielding gas (inert or active) and the welding parameters, different transfer modes can be achieved.

- Applications: Carbon steels, stainless steels, and aluminum alloys.

- Advantages: Cleaner welds, higher productivity, reduced slag removal, and compatibility with automation and robotics.

- Industries: Heavy fabrication, automotive manufacturing, shipbuilding, aerospace, pipeline construction, and general structural welding.

GMAW Metal Transfer Modes

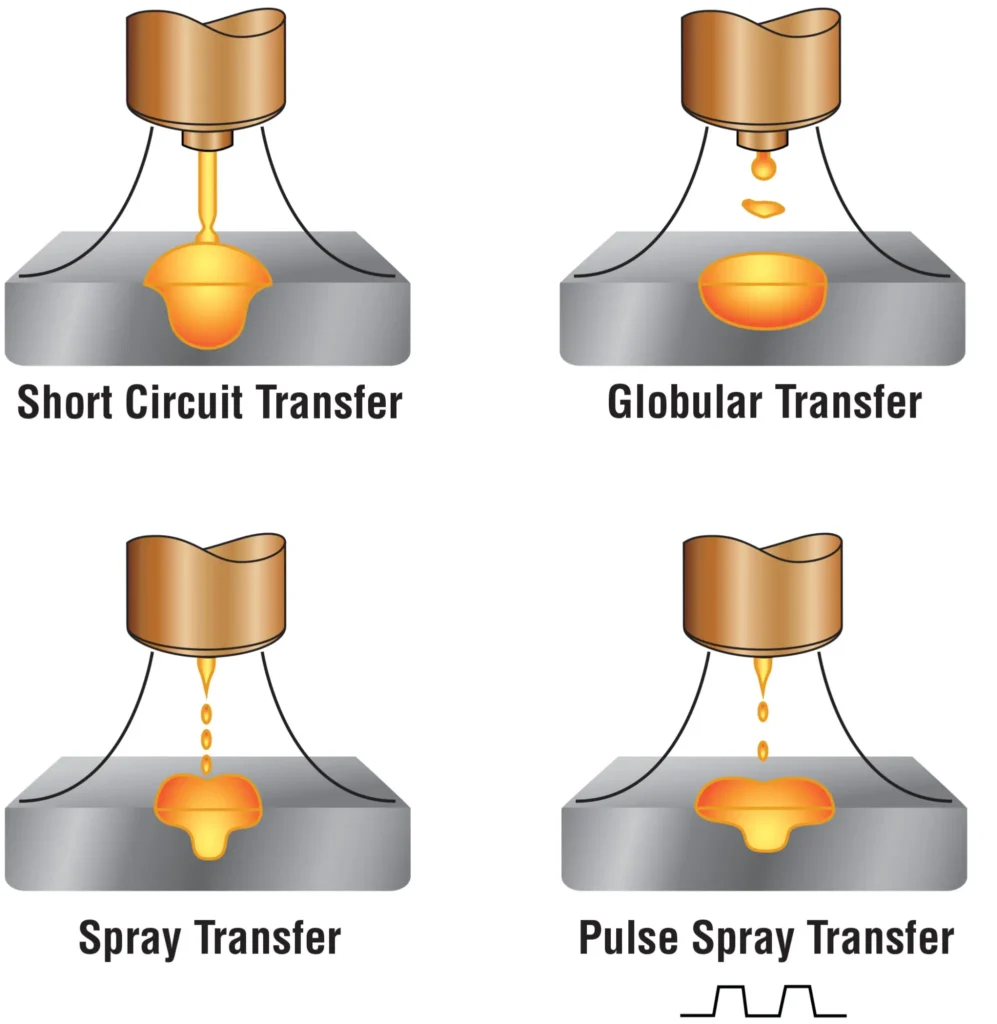

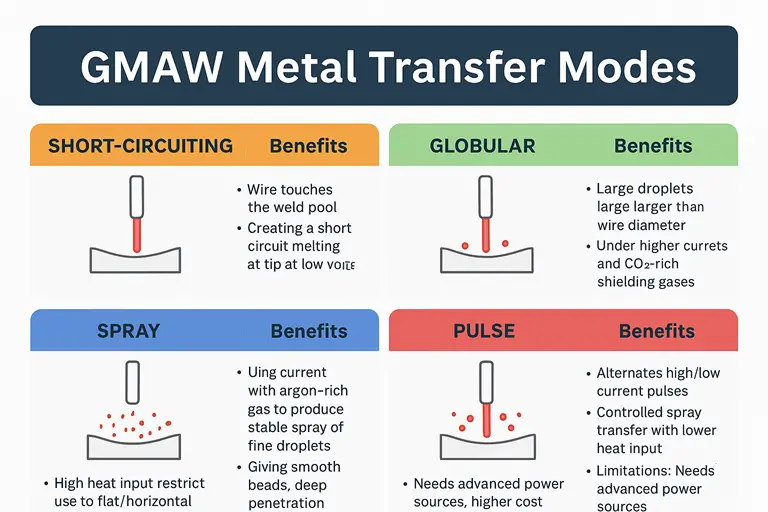

1. Short-Circuiting Transfer

In this mode, the wire electrode actually touches the weld pool, creating a short circuit. The current rises, melting the wire tip, and then the cycle repeats. This process operates at low voltage and current, making it highly controlled.

- Advantages:

- Excellent for thin materials.

- Suitable for out-of-position welding (vertical, overhead).

- Low heat input → reduces distortion in delicate work.

- Limitations:

- Produces higher spatter.

- Limited penetration depth.

- Not effective for thick sections unless multiple passes are made.

Typical Use: Sheet metal fabrication, automotive body repair, and thin-walled piping.

2. Globular Transfer

As current levels increase beyond short-circuiting but below spray mode, the transfer shifts to globular. Here, large molten droplets (greater than the wire diameter) form and detach irregularly under gravity.

- Advantages:

- Higher deposition rates.

- Deeper penetration than short-circuiting.

- Limitations:

- High spatter levels.

- Unstable arc.

- Poor weld bead appearance.

Typical Use: Welding thicker sections where appearance is not critical, often used with CO₂-rich shielding gases for cost efficiency.

3. Spray Transfer

Spray transfer occurs at higher current levels with argon-rich shielding gases. Here, the molten metal breaks into fine droplets that are propelled axially into the weld pool, resulting in a stable and smooth arc.

- Advantages:

- High deposition efficiency.

- Smooth, clean weld bead appearance.

- Excellent penetration.

- Limitations:

- High heat input makes it unsuitable for thin materials.

- Restricted to flat and horizontal positions.

Typical Use: Structural steel fabrication, aerospace components, pressure vessels, and situations where deep penetration is essential.

4. Pulsed Spray Transfer

An advanced variant of spray transfer, pulsed GMAW alternates between peak current (droplet transfer) and background current (arc maintained). This results in controlled droplet transfer with lower overall heat input.

- Advantages:

- Allows spray transfer benefits at lower average heat input.

- Suitable for thin materials and out-of-position welding.

- Reduces spatter compared to globular and short-circuiting modes.

- Limitations:

- Requires advanced, more expensive power sources.

- Complex setup and parameter tuning.

Typical Use: High-quality fabrication, aerospace, robotics, pipeline welding, and projects requiring versatility.

Modern Developments in GMAW Transfer

As industries demand higher quality and efficiency, newer controlled transfer technologies have evolved:

- RMD (Regulated Metal Deposition): Specially designed to minimize spatter and reduce heat input, providing better control over short-circuiting transfer. Widely used in root pass welding, especially for pipelines.

- STT (Surface Tension Transfer): A modification of short-circuiting that optimizes droplet detachment using advanced waveforms, enabling excellent out-of-position and pipe welding with minimal spatter.

- Cold Metal Transfer (CMT): A highly controlled short-circuiting process that retracts the wire during droplet transfer, making it ideal for thin sheets and dissimilar materials like aluminum to steel welding.

⚠️ Key Challenges in Transfer Mode Selection

Choosing the right transfer mode depends on several factors:

- Material type and thickness: Thin sheets vs. heavy sections.

- Welding position: Flat, horizontal, vertical, or overhead.

- Required penetration and appearance.

- Productivity goals: High deposition vs. low heat input.

- Equipment availability and cost: Advanced pulsed systems vs. conventional machines.

✅ Key Takeaways

- Short-Circuiting → Best for thin materials and out-of-position welding, but prone to spatter and shallow penetration.

- Globular → Works for thicker sections but produces high spatter and unstable arcs.

- Spray Transfer → Excellent for deep penetration and smooth beads, limited to flat/horizontal positions.

- Pulsed Spray → Most versatile, enabling spray transfer benefits with lower heat input across positions.

Ultimately, the best transfer mode depends on balancing weld quality, productivity, cost, and positional requirements.

📢 Conclusion

Mastering GMAW metal transfer modes is essential for welders, engineers, and industries that depend on strong, reliable welds. By understanding the characteristics of each mode and advancements like RMD, STT, and CMT, welding professionals can optimize their processes for efficiency, quality, and reduced rework.

A skilled welder not only selects the right mode for the job but also adjusts parameters, shielding gases, and techniques to achieve consistent, high-performance welds every time.