“In the world of metals, it’s not just what you’re made of—but how you’re treated that defines your strength.”

Heat treatment is a critical metallurgical process used across a wide range of industries—from automotive and aerospace to construction and manufacturing. It involves controlled heating and cooling of metals to alter their physical and mechanical properties without affecting their shape.

Understanding and mastering heat treatment is essential for any professional involved in welding, fabrication, or mechanical design.

Why PWHT is not Required for SS?

What Is Heat Treatment?

Heat treatment is the process of heating a metal to a specific temperature, maintaining it at that temperature for a desired period, and then cooling it at a controlled rate. This process manipulates the microstructure of metals to achieve desired mechanical properties like hardness, toughness, ductility, and strength.

Purpose of Heat Treatment

The goals of heat treatment are multifaceted:

- Improve mechanical properties (like hardness, strength, ductility, toughness)

- Enhance wear and corrosion resistance

- Relieve internal stresses from previous operations such as welding or machining

- Refine grain structure for better toughness

- Achieve microstructural transformations that improve performance

Four Key Heat Treatment Processes

Here are the most commonly used heat treatment processes, explained in detail:

1. Annealing

Purpose:

To soften metal, improve ductility, and relieve internal stresses.

Process:

Involves heating the metal above its recrystallization temperature, holding it at that temperature, and then slowly cooling it—usually in a furnace.

Applications:

- Improves machinability

- Prepares steel for further forming

- Restores ductility after cold working

Temperature Ranges:

- Carbon Steel (CS): ~815°C to 950°C

- Low Alloy Steel (LA): ~830°C to 980°C

Types of Annealing:

- Full Annealing

- Partial Annealing

- Sub-critical Annealing

2. Normalizing

Purpose:

To refine grain structure and improve mechanical toughness.

Process:

Metal is heated above its critical temperature and then air-cooled. This creates a more uniform, fine-grained structure.

Key Benefits:

- Enhances toughness

- Reduces internal stress

- Promotes uniform microstructure

Temperature Ranges:

- CS: ~830°C to 950°C

- LA: ~870°C to 1000°C

Note:

Normalized parts are typically stronger and harder than annealed parts.

3.Quenching

Purpose:

To increase hardness and strength by rapidly cooling the metal.

Process:

Metal is heated and held at austenitizing temperature and then rapidly cooled using water, oil, or air (depending on material and desired properties).

Temperature Ranges:

- CS: ~815°C to 900°C

- LA: ~860°C to 980°C

Cooling Media:

- Water (fast cooling)

- Oil (moderate cooling)

- Air (slow cooling for less distortion)

Important Note:

Quenching can lead to brittleness and internal stresses, which must be managed carefully.

4. Tempering

Purpose:

To reduce brittleness from quenching and improve toughness and ductility.

Process:

The quenched metal is reheated to a temperature below its critical point, held there for a time, and then air-cooled.

Temperature Range:

- CS & LA: ~150°C to 650°C

Outcome:

A balanced combination of hardness and toughness, making the component more durable and reliable under mechanical stress.

Challenges in Heat Treatment

Despite its many advantages, heat treatment comes with challenges that require attention:

- Maintaining accurate temperature control

- Risk of distortion and cracking, especially during rapid cooling

- Residual stress management

- Material-specific behavior during phase transformations

- High cost and energy consumption

Mitigation Measures:

- Use of automated furnaces with precision controls

- Proper fixture design to minimize deformation

- Post-heat-treatment inspections like hardness testing and microstructure analysis

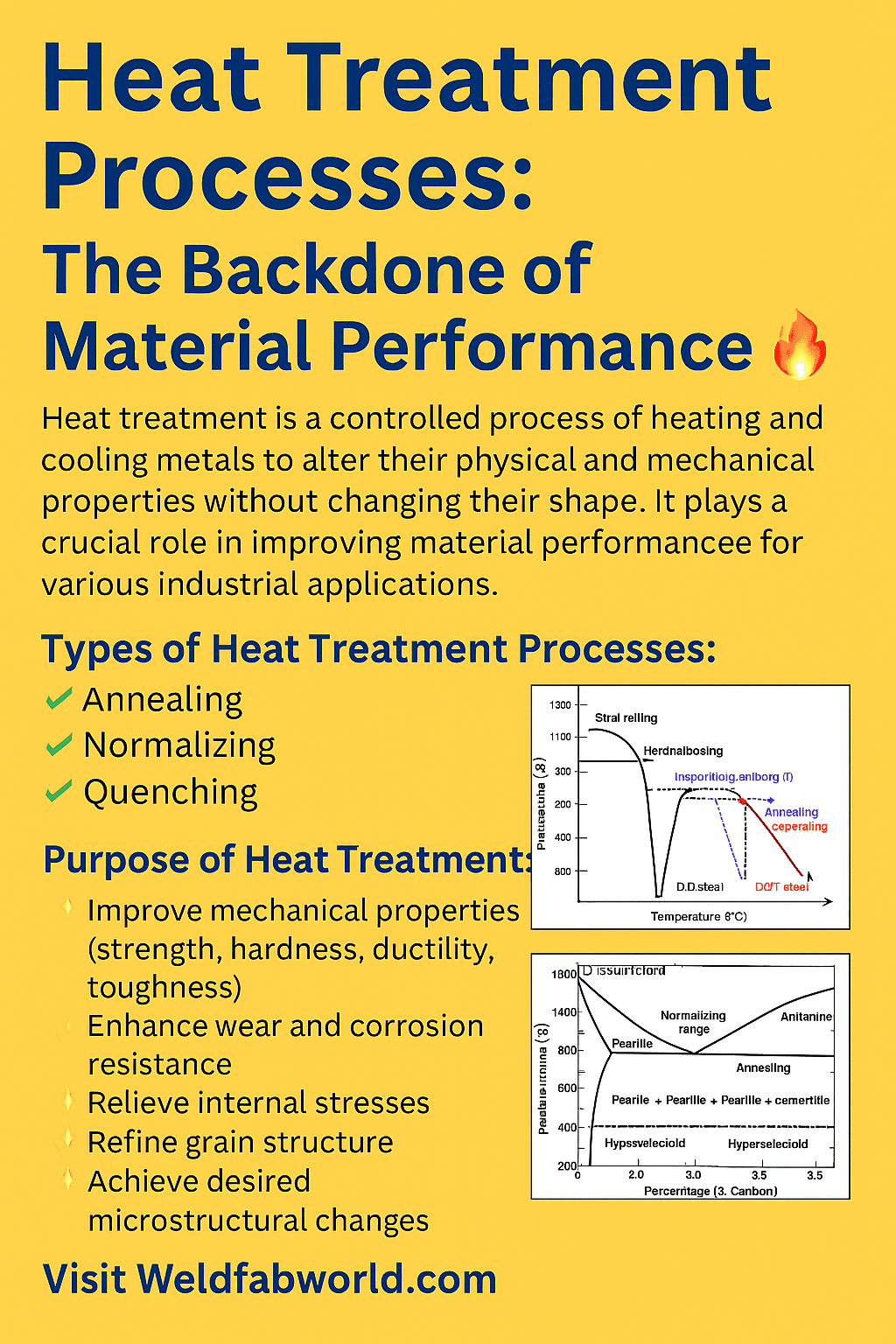

Heat Treatment Diagrams: Understanding Metallurgical Transformations

The diagrams in the image above offer critical insights:

- The Iron-Carbon Phase Diagram shows transformation ranges for different processes like annealing, normalizing, and hardening.

- The Time-Temperature-Transformation (TTT) and Continuous Cooling Transformation (CCT) curves show how cooling rates affect microstructures.

Understanding these diagrams is vital for designing correct heat treatment cycles.

Applications of Heat Treatment in Industry

| Industry | Purpose of Heat Treatment |

|---|---|

| Automotive | Enhance wear resistance, fatigue strength of gears, axles |

| Aerospace | Improve creep resistance and dimensional stability |

| Construction | Strengthen reinforcement bars and structural elements |

| Toolmaking | Achieve ultra-hard cutting edges |

Visit Weldfabworld.com for Expert Insights!

At Weldfabworld, we provide in-depth articles, tools, and resources on welding, fabrication, metallurgy, and manufacturing excellence. Whether you are a student, engineer, or industry veteran—our mission is to make technical knowledge accessible and practical.

Final Thoughts

Heat treatment is not just a supporting process—it is a strategic enabler of performance, quality, and reliability in engineered products. When done right, it transforms good materials into great components.

“You can forge the best steel, but without the right treatment, it won’t stand the test.”

Let’s Connect!

Are you optimizing your heat treatment processes for better performance and safety? Let’s connect and exchange insights.

Share this article with your colleagues and follow @Weldfabworld for more practical, real-world engineering knowledge.

#HeatTreatment #MaterialEngineering #ManufacturingExcellence #QualityControl #Welding #Metallurgy #EngineeringInsights #ISO9001 #QMS