Welding Procedure Specification (WPS) and Procedure Qualification Record (PQR) are essential documents in the world of welding, fabrication, and pressure equipment manufacturing. These documents ensure the welds produced meet code requirements, are repeatable, and result in safe, quality weldments. In most regulated industries such as oil & gas, power, and structural steel, the preparation and qualification of WPS and PQR is mandatory.

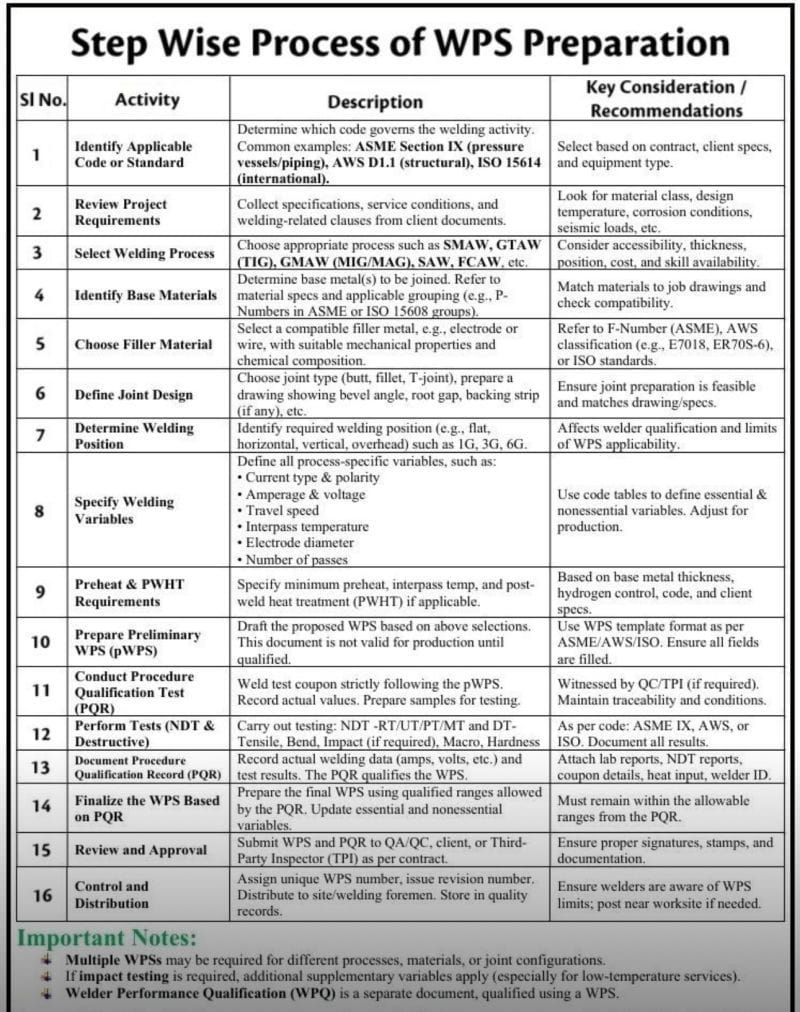

This guide offers a step-by-step process for preparing WPS and PQR based on the provided reference chart and integrates knowledge from ASME, AWS, and ISO standards.

✅ Step-by-Step Process for WPS and PQR Preparation

1. Identify Applicable Code or Standard

- Purpose: Establish which code governs the welding activity.

- Common Standards:

- ASME Section IX – Pressure vessels, boilers, piping.

- AWS D1.1 – Structural welding for buildings, bridges.

- ISO 15614 – International welding procedure qualification.

- Recommendation: Selection should align with customer contracts, project specifications, and regulatory requirements.

2. Review Project Requirements

- Collect detailed project specifications, base material data, service conditions (temperature, pressure, environment), and relevant customer clauses.

- Key Parameters:

- Material class

- Seismic and corrosion resistance

- Design temperature and service life

- Safety factors

3. Select Welding Process

- Choose the correct welding process based on joint configuration, accessibility, cost, and required mechanical properties.

- Examples:

- SMAW (Shielded Metal Arc Welding)

- GTAW (TIG)

- GMAW (MIG/MAG)

- FCAW, SAW, etc.

- Considerations: Availability of equipment, welder skills, and base material compatibility.

4. Identify Base Materials

- Define the base materials involved in the joint.

- Reference material grouping codes such as:

- P-Numbers (ASME)

- Group Numbers (AWS)

- ISO material groups (ISO 15608)

- Goal: Ensure proper joint compatibility and selection of filler metals.

5. Choose Filler Material

- Select a filler metal (electrode/wire) suitable for the base material and service conditions.

- Reference: F-Number (ASME), A-Number (chemistry), AWS classification (e.g., E7018, ER70S-6).

- Factors: Mechanical strength, toughness, corrosion resistance, ductility.

6. Define Joint Design

- Identify the joint type (butt, fillet, T-joint, etc.).

- Prepare a welding drawing that includes:

- Joint angle

- Root gap

- Backing strip (if used)

- Weld size and length

- Joint preparation plays a critical role in achieving defect-free welds.

7. Determine Welding Position

- Define the welding position for qualification (1G, 2G, 3G, 6G, etc.).

- Importance:

- Position affects welder qualification range.

- Impacts essential variable limits.

- Positions follow standards such as ASME IX or ISO 6947.

8. Specify Welding Variables

These are essential and non-essential variables that directly affect weld quality.

- Variables to Specify:

- Current type (AC/DC)

- Voltage and amperage

- Electrode diameter

- Travel speed

- Interpass temperature

- Heat input

- Number of passes

9. Preheat & Post Weld Heat Treatment (PWHT)

- Preheat: Prevents cracking by removing moisture and controlling cooling rates.

- PWHT: Improves toughness, relieves residual stress.

- Specified Based On:

- Base metal group

- Thickness

- Hydrogen control

- Customer requirement

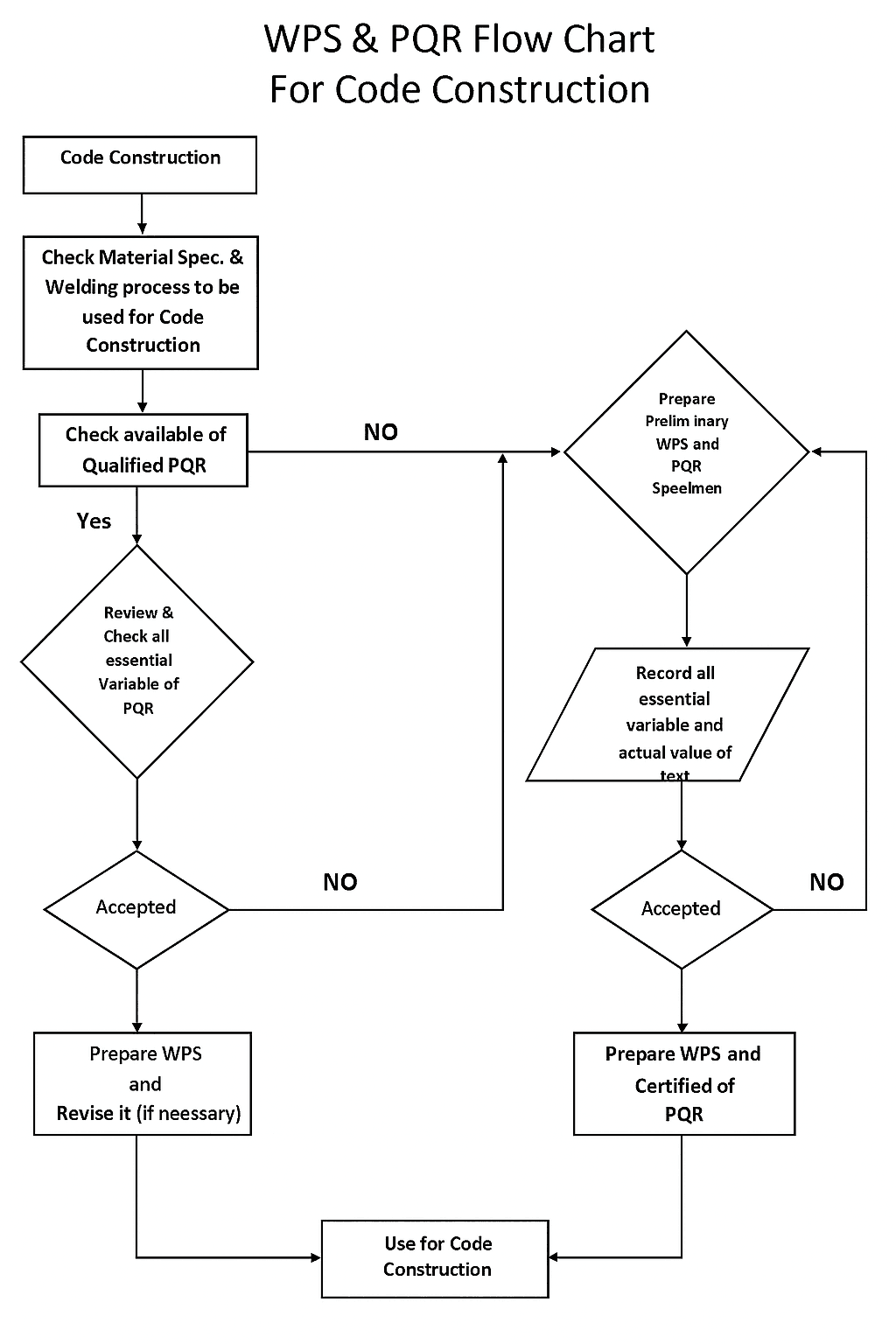

10. Prepare Preliminary WPS (pWPS)

- This is a draft version of WPS based on all selections above.

- Not valid for production until qualified.

- Should include all parameters in a standardized template (per ASME/AWS).

11. Conduct Procedure Qualification Test (PQT)

- Weld a test coupon strictly as per the pWPS.

- This weld will be tested to validate the procedure.

- Witnessing:

- Performed under supervision of QC, third-party inspector (TPI), or client.

12. Perform Tests (NDT & Destructive Testing)

- NDT:

- Radiographic Testing (RT)

- Ultrasonic Testing (UT)

- Magnetic Particle (MT)

- Liquid Penetrant (PT)

- Destructive Testing:

- Tensile

- Bend (root/face)

- Impact (Charpy)

- Macro examination

- Hardness (for PWHT cases)

13. Document Procedure Qualification Record (PQR)

- Record all variables used and results from the test coupon.

- Include:

- Welding parameters (amps, volts, travel speed)

- Base and filler materials

- NDT and mechanical test results

- Welder’s identity and qualification

14. Finalize WPS Based on PQR

- WPS is finalized using variables qualified in the PQR.

- It must stay within all qualified ranges:

- Example: Qualified 3G position doesn’t allow overhead welding unless tested.

- Update the WPS to reflect qualified limits and conditions.

15. Review and Approval

- Submit WPS and PQR for review.

- Reviewed and approved by:

- Quality Assurance (QA)

- Third-party inspection agency (TPI)

- Client or customer

- Must carry required signatures, stamps, and verification.

16. Control and Distribution

- Assign a unique WPS number for tracking.

- Issue to:

- Site engineers

- Welding supervisors

- Foremen

- Store records as part of project quality documentation.

- Important: Display WPS near the welding area if required.

📝 Important Notes

- Multiple WPSs may be needed for:

- Different materials

- Thicknesses

- Joint types

- Welding processes

- Additional tests may be required for:

- Low-temperature services (impact testing)

- Sour service (hardness + SSC testing)

- Welder Performance Qualification (WPQ) is a separate process that qualifies a welder using a qualified WPS.

📋 Templates and Documentation

- WPS Template:

- Header: WPS number, rev. number, date

- Welding process, base materials, filler metal, joint design, position, etc.

- Welding variables, preheat, PWHT, NDT requirements

- PQR Template:

- Record of actual welding data during qualification

- Testing results (NDT/DT)

- Acceptance criteria and test summary

🔍 Conclusion

WPS and PQR preparation is a disciplined process that ensures structural integrity and compliance with industry standards. By following the stepwise method outlined above, fabrication teams can achieve repeatable, quality welds and demonstrate compliance during audits and inspections.

Whether working under ASME, AWS, or ISO standards, this systematic approach helps safeguard product integrity, minimize rework, and ensure safety in critical applications.

📌 FAQs

Q: Can a welder use WPS without being qualified?

A: No, the welder must be qualified as per the approved WPS through a WPQ test.

Q: What if the welding parameters change slightly during production?

A: It depends whether the change affects essential variables. If yes, requalification may be needed.

Q: Is it mandatory to perform impact testing?

A: Only if required by service conditions (e.g., cryogenic service, seismic zones).