In pressure vessels, boilers, pipelines, and critical welded structures, weld spacing is more than a geometric rule—it’s a fundamental requirement to ensure safety, reliability, and compliance with international codes. The minimum distance between welds prevents heat-affected zones (HAZ) from overlapping, reduces residual stresses, and allows effective inspection and long-term performance.

1. Why Weld Spacing Matters

The welding process generates high temperatures, altering the microstructure around the weld, known as the Heat-Affected Zone (HAZ). When welds are placed too close together, their HAZ regions can overlap, leading to:

- Grain coarsening and metallurgical weakness.

- Distortion or warping of the structure.

- Higher residual stress concentration.

- Difficulty in performing reliable non-destructive testing (NDT).

- Reduced fatigue resistance and crack propagation risk.

In short: Proper weld spacing ensures structural integrity, long-term durability, and compliance with fabrication codes.

2. Minimum Weld Spacing as per Codes and Standards

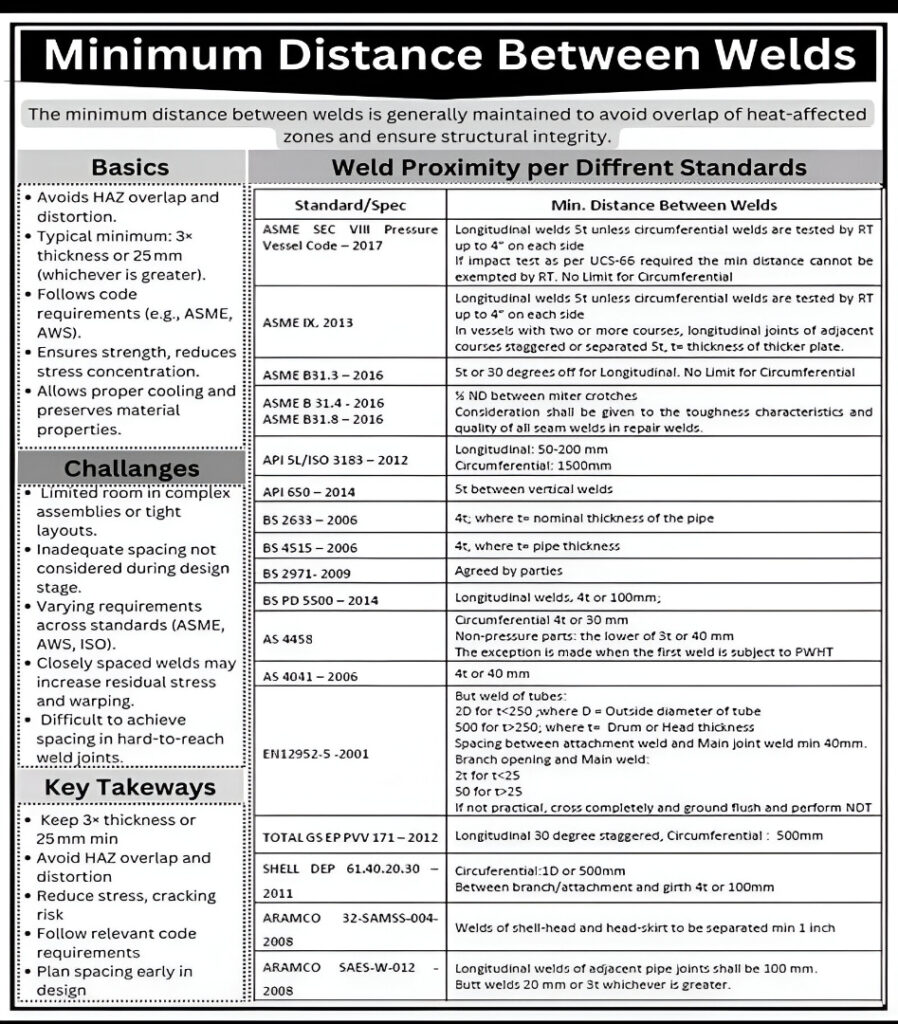

Different codes and standards provide specific guidance on the minimum distance between welds, usually expressed as multiples of thickness (t) or fixed dimensions.

| Standard / Spec | Minimum Distance Between Welds |

|---|---|

| ASME Sec VIII (2017) | Longitudinal welds unless circumferential welds are tested by RT, up to 4″ on each side. If UCS-66 impact test applies, cannot be exempted by RT. No limit for circumferential. |

| ASME IX (2013) | Similar to Section VIII, 4″ spacing rule applies for longitudinal welds unless RT tested. |

| ASME B31.3 (2016) | 30° separation for longitudinal welds. |

| ASME B31.4 & B31.8 (2016) | 5 × nominal diameter from miter crotches. Consider material toughness for repair welds. |

| API 5L / ISO 3183 (2012) | Longitudinal: 50–200 mm; Circumferential: 1500 mm. |

| API 650 (2014) | 5 × shell thickness between vertical welds. |

| BS 2633 (2006) | 4 × nominal pipe wall thickness. |

| BS 4515 (2006) | 4 × pipe wall thickness (toe-to-toe). |

| BS 2971 (2009) | By agreement between parties. |

| PD 5500 (2014) | Longitudinal welds: 4t or 100 mm. |

| AS 4041 (2006) | 4t or 40 mm (for piping). |

| AS 4458 | Circumferential welds: 4t or 30 mm. Non-pressure parts: lower of 3t or 40 mm. |

| EN 12952-5 (2001) | Tubes: 20t for <25 mm, 500t for >250 mm; Branch openings: 40–50 mm min. |

| TOTAL GS EP PVV 171 (2012) | Longitudinal: 30° staggered; Circumferential: 500 mm. |

| SHELL DEP 61.40.20.30 (2011) | Circumferential: 1D or 500 mm; Branch-to-girth: 4t or 100 mm. |

| ARAMCO 32-SAMSS-004 (2008) | Welds of shell-head and head-skirt separated by ≥1 inch. |

| ARAMCO SAES-W-012 (2008) | Longitudinal welds of adjacent pipe joints: 100 mm min; Butt welds: ≥20 mm or 3t. |

3. Challenges in Maintaining Weld Spacing

While codes set the minimum requirements, practical challenges often arise:

- Tight layouts in complex assemblies limit available spacing.

- Inadequate design foresight may lead to non-compliance during fabrication.

- Different standards (ASME, API, ISO, BS) specify varying spacing rules, creating confusion.

- Closely spaced welds may increase distortion and residual stresses.

- Access restrictions make spacing compliance hard in confined areas.

4. Engineering Best Practices

Beyond code requirements, welding engineers follow practical spacing guidelines to improve weld reliability:

- Keep 3 × thickness or 25 mm (minimum rule of thumb).

- Carbon steel / low alloy steel: At least 2 inches or 2t.

- High-strength steels & aluminum alloys: ≥40 mm to prevent cracking.

- Super duplex / nickel alloys: Strict spacing to avoid HAZ softening.

- Circumferential welds in vessels: ≥250 mm separation.

- Longitudinal welds in shells: Offset by 30° or ≥5t in adjacent courses.

- Branch connections: Maintain ≥40 mm clearance between branch weld and main seam.

5. Inspection and Design Recommendations

To ensure both compliance and practicality:

- Plan spacing during design stage to avoid field rework.

- Document spacing in WPS and drawings for clarity.

- Use NDT effectively: Ensure RT/UT probes can access without weld interference.

- Sequence welds strategically to minimize distortion.

- Consider PWHT (Post-Weld Heat Treatment): Closely spaced welds may heat unevenly, reducing stress-relief effectiveness.

6. Key Takeaways

- Always follow the stricter requirement between code and client specifications.

- Maintain 3 × thickness or ≥25 mm as a safe baseline when codes don’t apply.

- Proper spacing avoids HAZ overlap, cracking, and distortion.

- Early design-stage planning prevents costly fabrication rework.

Conclusion

Minimum weld spacing is not just a compliance checkbox—it is essential to achieving mechanical integrity, ease of inspection, and long-term reliability of welded equipment. By following code requirements, applying sound engineering judgment, and planning spacing during design, industries can ensure safe and efficient operation of pressure equipment and piping systems.