For fabrication of any equipment we require welders and welding operators must be qualified as per the qualification standard referred by the construction code. Whenever construction is as per ASME construction codes (like ASME B31.1, B31.3 or ASME section VIII) ASME section IX is used for the qualification of the procedure and welder. Welder is necessary to be qualified as per the requirements of ASME section IX.

In this article we will discuss for the qualification requirements for the welder’s and welding operator’s. For understanding this article effectively one must understand the difference between welder and welding operator which we have already discussed in our previous article if you are not aware about these terms you may visit at this link.

What does qualified welder or welding operator means?

A qualified welder or welding operator is one who has meet’s the testing requirement of ASME section IX (if qualification standard is section IX) and possess skills to produce sound welds as per the requirement of the construction code, which are visually acceptable and meet the requirements of the code. The term “Welding Performance Qualification” is used in section IX for the qualification of the welder which will be used in this article from now.

Purpose of test: The performance qualification tests are intended to determine the ability of the welder and welding operator to produce the sound welds.

Test Requirements: Every organization shall qualify the welder or welding operator to be used in production as per Article III section IX which specifies the requirements for the test and records to be maintained which we have summarized below:

For qualifying welder/welding operator test coupon shall be welded in accordance with qualified welding procedure specification (WPS) or standard welding procedure qualification (SWPS) , preheat and PWHT may not necessary to be carried out if required by WPS/SWPS.

Testing Required: For the performance qualification welder may be tested for mechanical or volumetric examination.

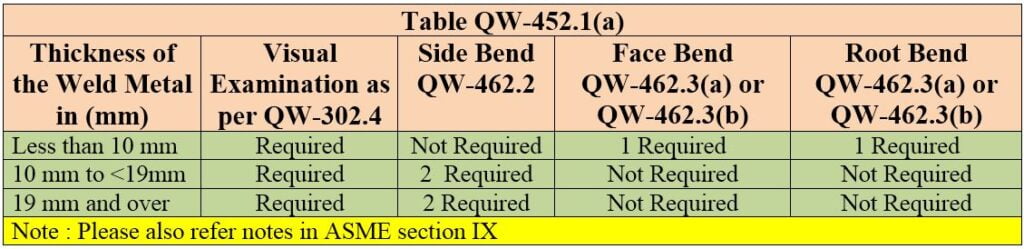

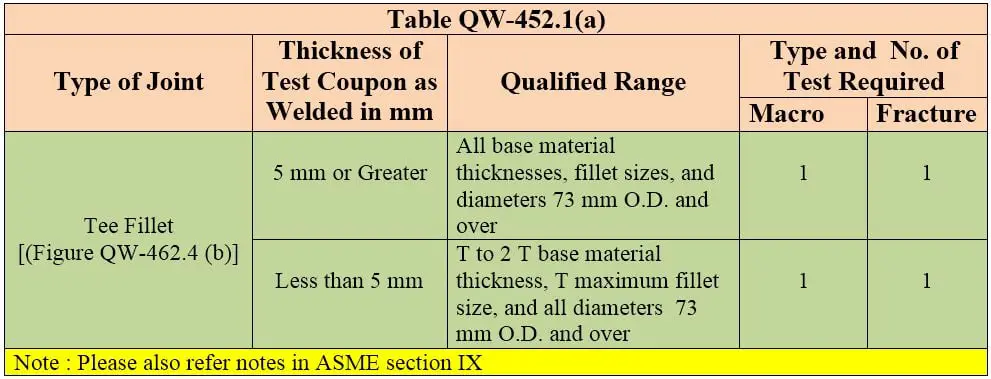

Qualification by Mechanical Testing: When qualifying welder/welding operator with mechanical testing the type and number of specimen required for mechanical testing shall be in accordance with QW-452, we have summarized the requirements below:

Mechanical testing can be used to qualify the welder in any material and thickness of weld deposit. The method and acceptance as per QW-160 or QW-180, as applicable. QW-160 is applicable for groove welds tests and QW-180 is applicable for fillet weld tests.

Qualification by Volumetric NDE: When qualifying welder/ welding operator by volumetric NDE when permitted by section, the minimum length to be examined when qualifying with volumetric examination shall be 150mm and shall include entire weld circumference. If qualifying welder in smaller diameter and the minimum 150 mm length cannot be achieved by single test coupon multiple test coupons to be welded to qualify welder/welding operator (maximum 4 nos. of test coupon shall be used).

Welder and welding operator can also be qualified over production weld by volumetric examination. But for qualification of welding operator with production weld the minimum testing length shall be 1 meter.

Volumetric examination can be used to qualify welder/welding operator when making a groove weld using welding process SMAW, SAW, GTAW, PAW and GMAW (except short circuiting mode for radiographic examination) or a combination of these processes, except for P‐No. 21 through P‐No. 26,

P‐No. 51 through P‐No. 53, and P‐No. 61 through P‐No. 62 metals. Welders making groove welds in P‐No. 21 through P‐No. 26 and P‐No. 51 through P‐No. 53 metals with the GTAW process may also be qualified by volumetric NDE per QW-191.

Volumetric NDE method and acceptance are specified in QW-191. As per QW-191 with radiographic examination and ultrasonic examination welder can be qualified. Radiographic examination can be used to qualify welder for any thickness but ultrasonic examination is acceptable only for thickness 6 mm and above.

Note: Volumetric NDE cannot be used for qualification of welder/ welding operator in Fillet joints.