In this article we will discuss about the tube to tubesheet welder and welding operator qualification as per BPVC ASME Section IX.

Tube to Tubesheet Welding

Tube to tube sheet welding is a special kind of welding, both process and technique wise. Essentially the parameters, techniques adopted for a groove weld will not work for this type of weld joint. Tube to Tubesheet welding is a critical weld and a very specific weld joint, whose integrity cannot be assured by groove welding qualification alone. The failure of a tube to tubesheet welding may cost more and whole exchange will be waste.

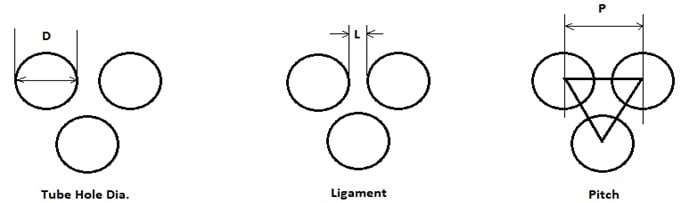

Important Terminology for Tube to Tubesheet joint type as per ASME:

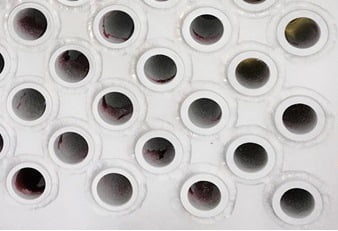

Tube Hole, D: It is the through hole in tubesheet in which tube is inserted.

Ligament, L: It is the shortest distance between edge of the adjacent tube hole in the tubesheet.

Pitch, P : It is the centre to centre distance of tube holes.

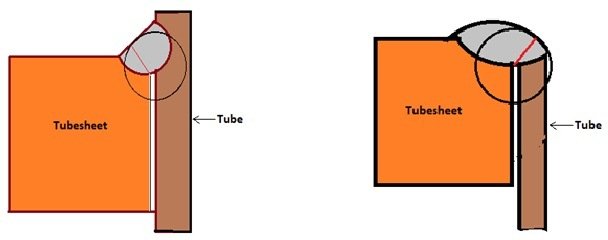

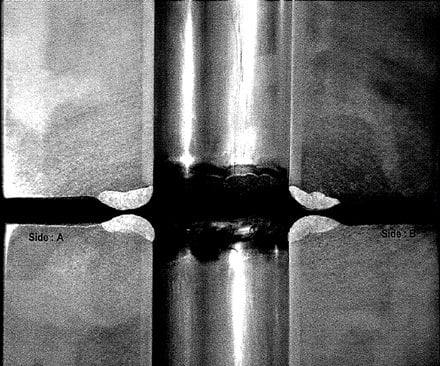

Minimum Leak Path: It is the distance from the root of the weld to the surface nearest the root (red line show in below figure 3, is the shortest way i.e. MLP). MLP must equal that required by the design or by the Construction Code or client requirement.

For the strength weld joint MPL is the minimum distance required by a fluid from root side of the weld to get leaked from face side i.e. tubesheet side.

While designing the heat exchanger, critical and potential leak path of the fluid is tube to tubesheet joint. Hence, tube-to-tubesheet joint design is considered as the most important factor.

Tube-to-Tubesheet Welder Qualification

1. The mockup assembly shall essentially duplicate the tube-to-tubesheet weld joint design to be used in production, within the limits of the essential variables of QW-350 in addition to the variables of Table QW-388.

2. A minimum of 5 mock-up tube-to-tubesheet welds are required to qualify each welder or welding operator. (Refer QW-193.2)

3. PWHT may be omitted (Refer QW-193.2)

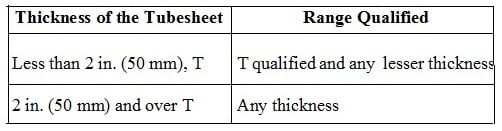

Tubesheet Thickness Limit for Welder Qualification (Refer QW-193.1)

Tube-to-Tubesheet Welder & Welding Operator Qualification (QW-387)

1. When the applicable Code Section requires the use of QW-193 for tube-to-tubesheet demonstration mock up qualification tests, QW-193.2 shall apply.

–ASME BPVC Section VIII Division 1 does not stipulate as a mandatory requirement to apply QW-193, it is manufacturer’s option to choose between QW-193 or normal welder qualification in accordance with QW-303.1.

–However, in case of ASME BPVC Section VIII Division 2, application of QW-193 is mandatory in accordance with para. 6.3.4.

2. If specific qualification test requirements are not specified by the applicable Code Section, welders and welding operators shall be qualified with one of the following methods:

–Demonstration mockup per the requirements of QW-193.2, as described above.

–A groove-weld qualification as per the requirements of QW-303.1

The welder or welding operator who pass the required test for groove weld shall be qualified for the welding of tube-to-tubesheet joint and in addition welding position, diameter restrictions and essential variable of QW-350 or QW-360 shall also applicable.

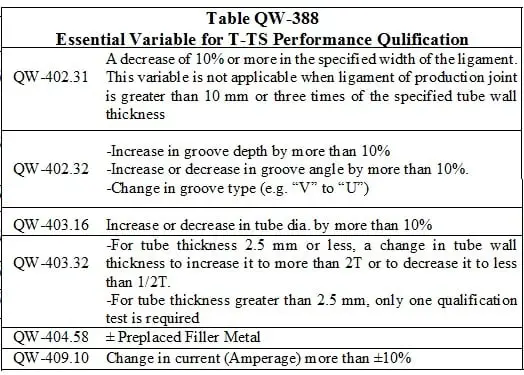

Essential Variables for Tube-to-Tubesheet Performance Qualification

In addition to this article, please refer ASME BVPC SECTION IX with errata mentioned in below link, as some typo error is in code ASME BPVC Section IX, Ed. 2019.

https://cstools.asme.org/csconnect/CommitteePages.cfm?Committee=N20120000&CommitteeErrata=yes

Testing Required for Tube-to-tubesheet Performance Qualification:

Visual Examination: The weld shall show complete fusion, be free from crack or porosity and have no evidence of burning through the tube wall thickness.

Liquid Penetrant Examination: Shall meet the requirement of ASME Section V, Article 6.

Acceptance Criteria:

-No relevant linear indication

-Rounded indication shall not be greater than 5 mm

-Three or less rounded indication in a line separated by 1.5 mm are acceptable.

Macro Examination: The mockup welds shall be sectioned through the center of the tube for macro examination. The four exposed surface shall be smoothed and etched to give clear definition of the weld and HAZ. Using magnification of 10X to 20X.

Acceptance Criteria:

-Must achieve minimum leak path (MLP) dimension required by the design.

-No Cracking

-Complete fusion of the weld deposit into the tubesheet and the tube wall thickness.

Nice literature.

Good presentation, would help knowledge seekers

Very informative. It would be help to understand the TTS and Welders qualification.

Thanks For sharing.

How can we calculate MPL?Is there any formula in any construction standard ?

Good and informative literature for Tube to tubesheet weld